Cost of CNC: A Comprehensive Guide [+Price Comparison]

Sort out all details of CNC cost and the price comparison between several key service providers.

Introduction

CNC machining is a key technology in modern manufacturing, offering precision and flexibility. However, the cost of CNC services can vary widely depending on factors such as part complexity, materials, machine type etc.

This guide will break down the key cost components, compare prices across different CNC services, and provide tips on how to optimize your budget. By the end, you'll have a clear understanding of CNC pricing to make informed decisions for your project.

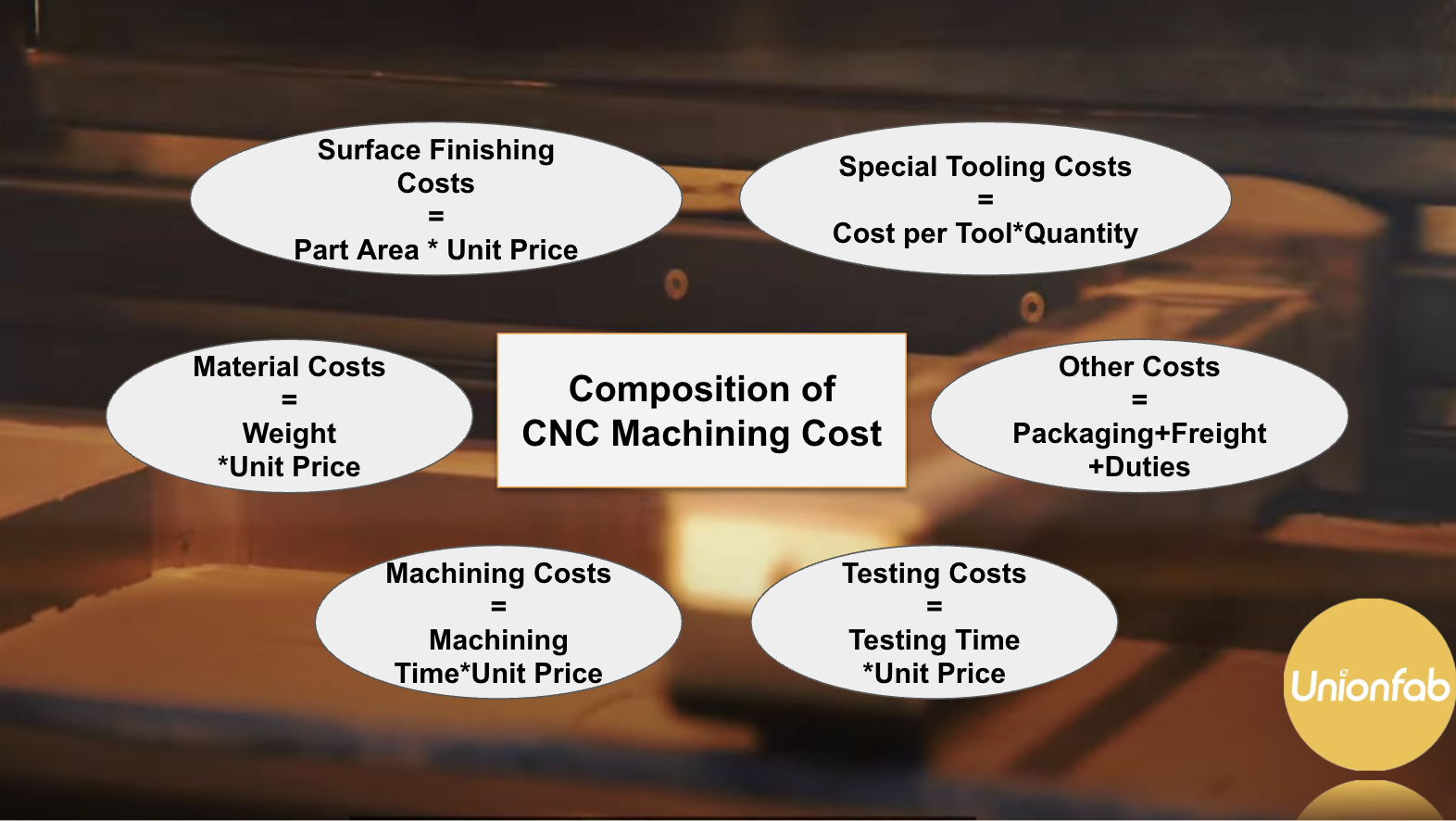

Composition of CNC Machining Cost

The total cost of CNC machining can be broken down into several components as follows.

Material Cost

Material cost typically represents a significant portion of the total machining cost. The type of material chosen for a part directly influences both the cost of raw material and the complexity of the machining process.

Raw Material: The cost of the raw material used in CNC machining, such as metal, plastic, or composite, can vary widely depending on the type, grade, size, and quality required.

Waste Material: CNC machining is a subtractive process, meaning excess material is removed to form the desired part. This waste factor must be considered, especially for expensive materials.

Price of Common CNC Materials Materials used in CNC machining vary widely and can include metals (aluminum, steel, titanium, etc.), plastics, ceramics, and composite materials.

Here we have compared the price of common CNC materials for your references.

Category | Material | Unit Price (USD/kg) |

|---|---|---|

Metals | Aluminum | $ |

Copper | $$$ | |

Brass | $$$ | |

Bronze | $$$ | |

Steel | $$$ | |

Stainless Steel | $$$ | |

Magnesium | $$$$$ | |

Titanium | $$$$$ | |

Plastics | PC (Polycarbonate) | $$$ |

ABS | $$$ | |

PEEK | $$$$$ | |

PMMA (Acrylic) | $ | |

POM | $$ | |

PTFE (Teflon) | $$ | |

PA (Nylon) | $$ | |

Composites | FR4 (Epoxy Fiberglass) | $$ |

Synthetic stone (CDM) | $$ | |

Bakelite PF | $$ | |

Graphite | $$ | |

Ceramics | Silicon Nitride (Si3N4) | $$$$$ |

Alumina (Al2O3) | $$$$$ | |

Zirconia (ZrO2) | $$$$$ |

Machining Cost

Machining cost refers to the expenses incurred during the actual production of parts on the CNC machine. This cost is influenced by several factors, including the complexity of the part design, the type of CNC machine used, and the time required to complete the machining process.

Machining Time: CNC machines operate at an hourly rate. Parts with intricate geometries or high precision require more machining time, which increases costs.

Machine Type and Capability: Advanced CNC machines with higher capabilities (such as multi-axis machines) typically cost more to operate than basic 3-axis machines. These machines may also require skilled operators, contributing to the overall cost. The following is a reference price.

CNC Type | Rate |

|---|---|

3-axis | $40/hr |

4-axis | $45-50/hr |

5-axis | $75-120/hr |

Special Tooling Cost

Special tooling costs refer to any custom or non-standard tools required for the CNC machining process. These tools are often needed for specialized operations or to accommodate unique design features that cannot be handled with standard tooling. If a specific part requires custom or specialized tools, such as custom cutters, fixtures, or jigs, the costs of creating and maintaining these tools can add up.

Heat Treatment Cost

Heat treatment is an important part of CNC machining, especially for metals, to improve the material's properties such as hardness, tensile strength, toughness, and resistance to wear and corrosion. Here we have attached the estimated cost for different heat treatment costs.

Heat Treatment Process | Estimated Cost (USD per part) |

|---|---|

Annealing | $0.50 to $3.00 |

Hardening and Tempering | $5.00 to $25.00 |

Case Hardening | $10.00 to $50.00 |

Stress Relieving | $1.00 to $5.00 |

Titanium Heat Treatment | $100.00 to $200.00 |

Surface Finishing Cost

Surface finishing is the final stage in CNC machining, where the part's surface is refined to meet specific aesthetic or functional requirements. This cost depends on the type of finishing required, whether it’s a simple deburring or a more complex coating process. Here is the estimated cost for your reference.

Surface Finish Process | Estimated Cost (USD per part) |

|---|---|

Polishing | $2.00 to $15.00 |

Anodizing | $3.00 to $12.00 |

Painting or Coating | $5.00 to $20.00 |

Electroplating (Nickel/Chrome) | $10.00 to $30.00 |

Sandblasting / Media Blasting | $2.00 to $10.00 |

Passivation | $3.00 to $8.00 |

Laser Etching / Engraving | $5.00 to $20.00 |

Testing Cost

Testing ensures that the CNC machined parts meet the required specifications and performance standards. Depending on the part’s function and industry requirements, testing can be extensive or minimal, influencing the overall cost.

Other Cost

Packaging Fees Packaging fees may also be added to the final cost, especially for fragile or complex parts that require special care during transportation.

Standard Packaging (Free)

The most common packaging is the corrugated box with bubble wrap or foam paddings inside.

Protective Packaging (Paid)

Depending on the final product, additional protective packaging such as wooden crates or even custom-made flight cases may be required.

Here's a general breakdown of costs:

Wooden Crates:

* Simple wooden crates for small to medium-sized parts typically range from $50 to $300.

* For larger or more complex parts, prices can go up to $500 or more, depending on the wood type, size, and level of reinforcement needed.

Custom-Made Flight Cases:

* Basic custom flight cases can cost around $200 to $500 for small items.

* For larger, fully customized cases with specialized padding and materials, prices can range from $800 to $2,000 or more.

Shipping Fees

Shipping fees are another important consideration when calculating the total cnc cost, especially for cross-border orders. Different carriers (e.g., USPS, FedEx, DHL) offer varying rates depending on the destination, size, weight, and urgency of delivery.

Customs Duties

When shipping cnc parts internationally, customs duties may apply, depending on the destination country’s import regulations. Customs duties can vary widely, but typically range between 5% to 20% of the total product value, depending on the country’s specific tariff regulations.

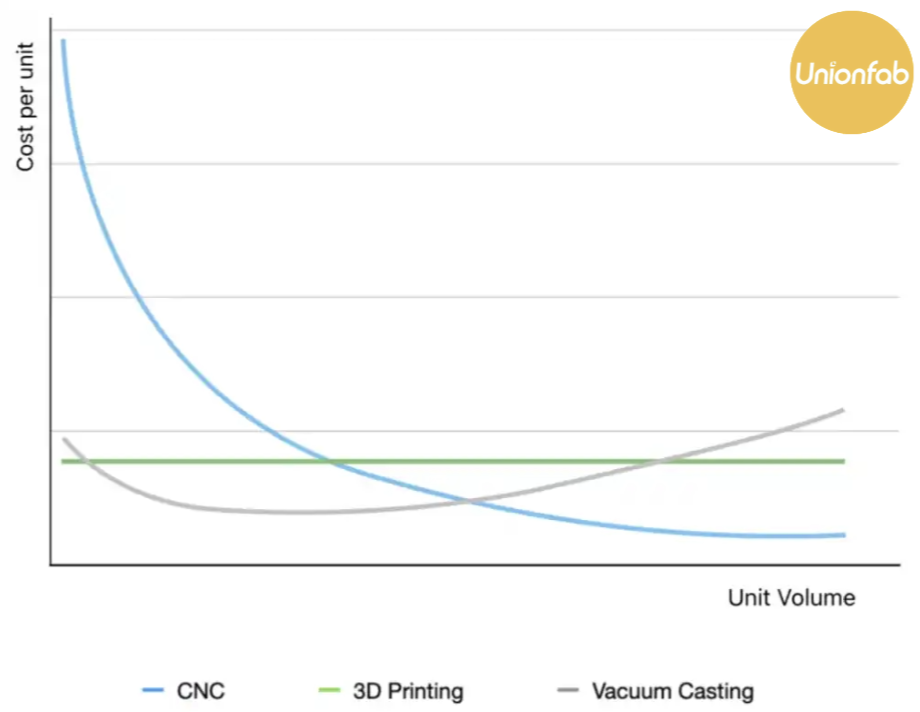

Relationship Between Cost and Quantity

The cost of CNC machining generally decreases with an increase in quantity due to the principle of economies of scale.

To present it more clearly, we have created a comparison chart with 3D printing and casting, showing the relationship between processing quantity and price for all three methods.

Want to know more differences about these 3 manufacturing methods, you can read this article: 3D Printing vs. CNC vs. Vacuum Casting: the Ultimate Comparison

Cost Comparison: Hubs VS. Xometry VS. Rapiddirect VS. Unionfab

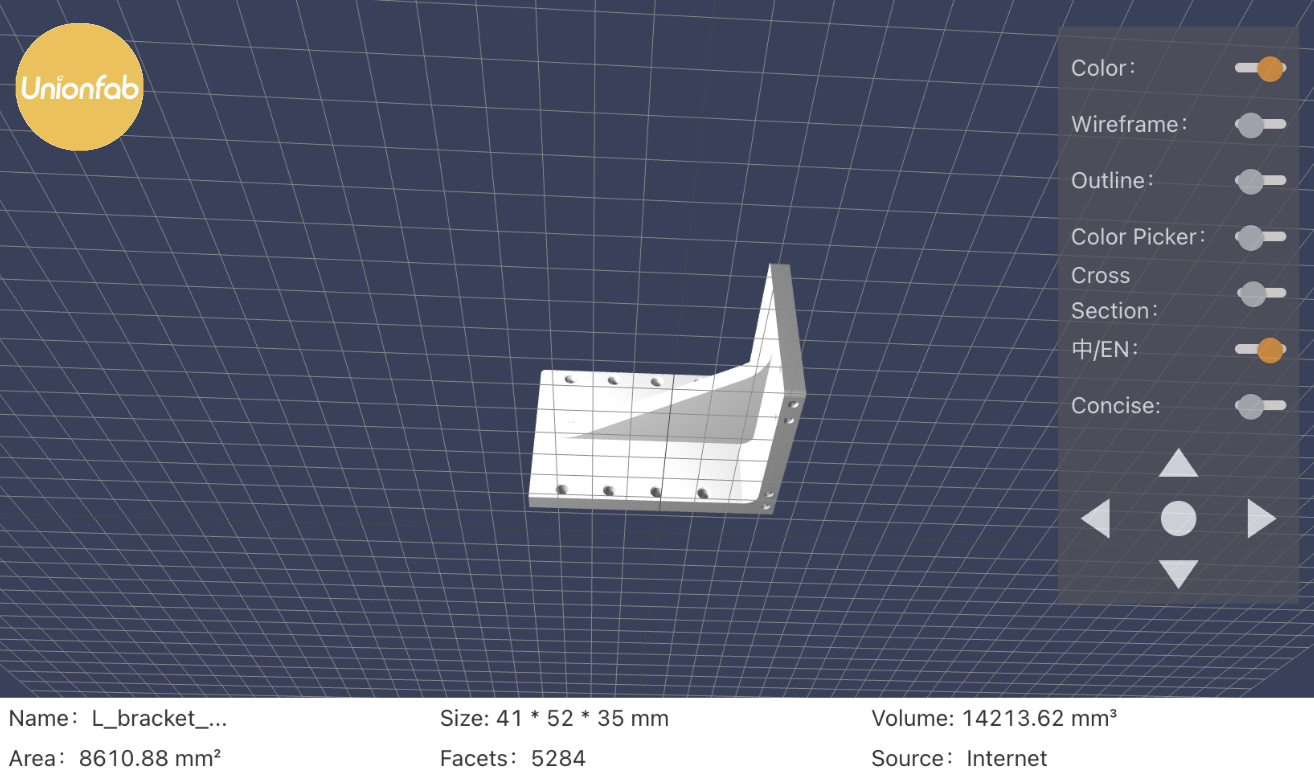

To compare Unionfab’s cnc prices with several well-known CNC service providers in the market, we uploaded the same 3D model to their automated quoting systems and kept all other parameters consistent. The printing specification and the final price comparison chart are provided below for your reference.

Specification

Dimension of the Model: 41 × 52 × 35 mm

Material: Aluminum 6061

Quantity: 500

Roughness: As machined (Ra3.2)

Finish: No finish

*Price Comparison

Hubs | Xometry | Rapiddirect | Unionfab | |

|---|---|---|---|---|

Lead Time (Business Day) | 30 | 14 | 23 | 12 |

Price Per Part | US$10. 19 | US$8.17 | US$17.13 | US$6.62 |

Total Price | US$5095 | US$4085 | US$8565 | US$3310.34 |

*The first three prices were collected from their automated quoting systems and may differ from the actual quotes. Therefore, they should only be used as a reference.

Unionfab’s price has been manually verified and can be considered the actual machining cost for this model. Additionally, if you have never placed an order with Unionfab before, sign up to get your 10% discount now!

Unionfab’ s CNC Services — Customer First

Certification

ISO9001 Quality Assurance

Production Capacity

50+ Metals, Plastics, and Composites

50+ Production Equipment

10+ Testing Equipment

Post-processing Available

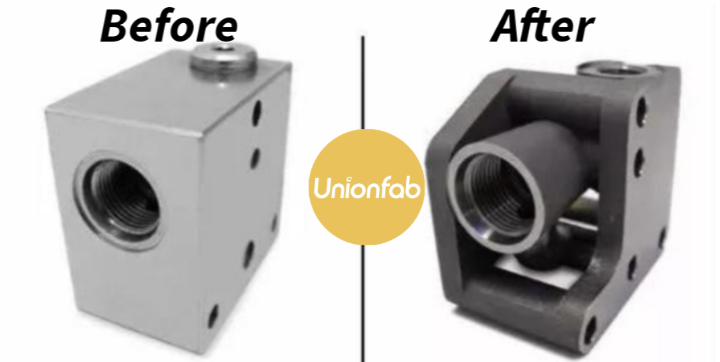

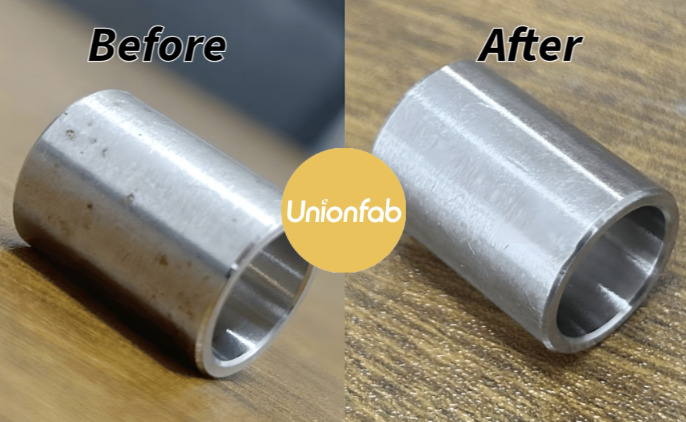

Post-processing | Effect |

|---|---|

Anodizing |

|

Electroplating |

|

Screen Printing |

|

Galvanizing |

|

Painting |

|

Blackening/Black Oxide Treatment |

|

Sandblasting |

|

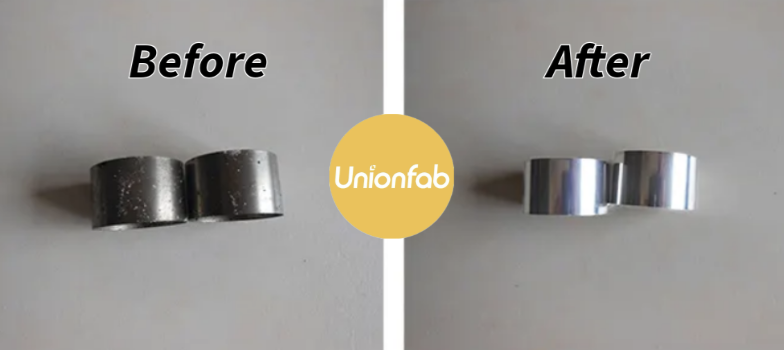

Polishing |

|

Passivation |

|

Monthly Supply Capacity: $2 Million

Delivery Capacity

Aim:

100% On-Time Delivery, ≥98% Shipment Quality, 100% Customer Satisfaction

Commitment:

5-7 Days for Small Batches of Small Parts

9-12 Days for Small Batches of Large Parts

Products Display