Guide to Clear Resin 3D Printing [+ Free Cost Calculator]

Manufacturing clear parts in traditional methods like injection molding and CNC machining involves challenges such as high mold costs, long lead times, and difficulty achieving clear, smooth surfaces, especially for complex shapes.

Clear resin 3D printing solves these issues by eliminating molds, enabling faster, cost-effective production with high transparency and smooth surfaces, making it ideal for small batches, rapid prototyping, and custom designs.

In this article, we will break down clear resin 3D printing and compare different service providers to help you choose the most suitable one.

How Does Clear Resin 3D Printing Work?

When applying 3D printing technology to manufacture clear parts, clear resins are the ideal material choice. In this section, we will break down the process into three key aspects: materials, technologies, and post-processing.

Types of Transparent Resins

Transparent resins for 3D printing can be categorized into the following types based on their properties: Standard, Optical, High-Temperature, Chemical-Resistant, Flexible, and High-Strength Clear Resins. However, for most clear 3D printing applications (prototyping, concept testing, and visual representation etc.) , standard clear resin is sufficient to meet the requirements. So, it’s fair to say that standard clear resin is the most commonly used material in clear 3D printing.

The following is the detailed data about the mechanical property of standard clear resin that Unionfab uses.

Property | Discription |

|---|---|

Appearance | Nearly colorless transparent viscous liquid |

Viscosity | 200mPa·s@25 °C |

Density | ~1.12 g/cm3@25 °C |

Tensile Strength | 48MPa |

Flexural Strength | 86MPa |

Flexural Modulus | 2100MPa |

Elongation at Break | 12% |

For more details, please download the datasheet.

Technologies Suitable for Clear Resin 3D Printing

Two of the most widely used technologies are SLA (Stereolithography) and DLP (Digital Light Processing). These technologies are ideal for achieving high precision and transparency, making them the go-to choices for printing detailed and clear parts. Here’s an introduction to both:

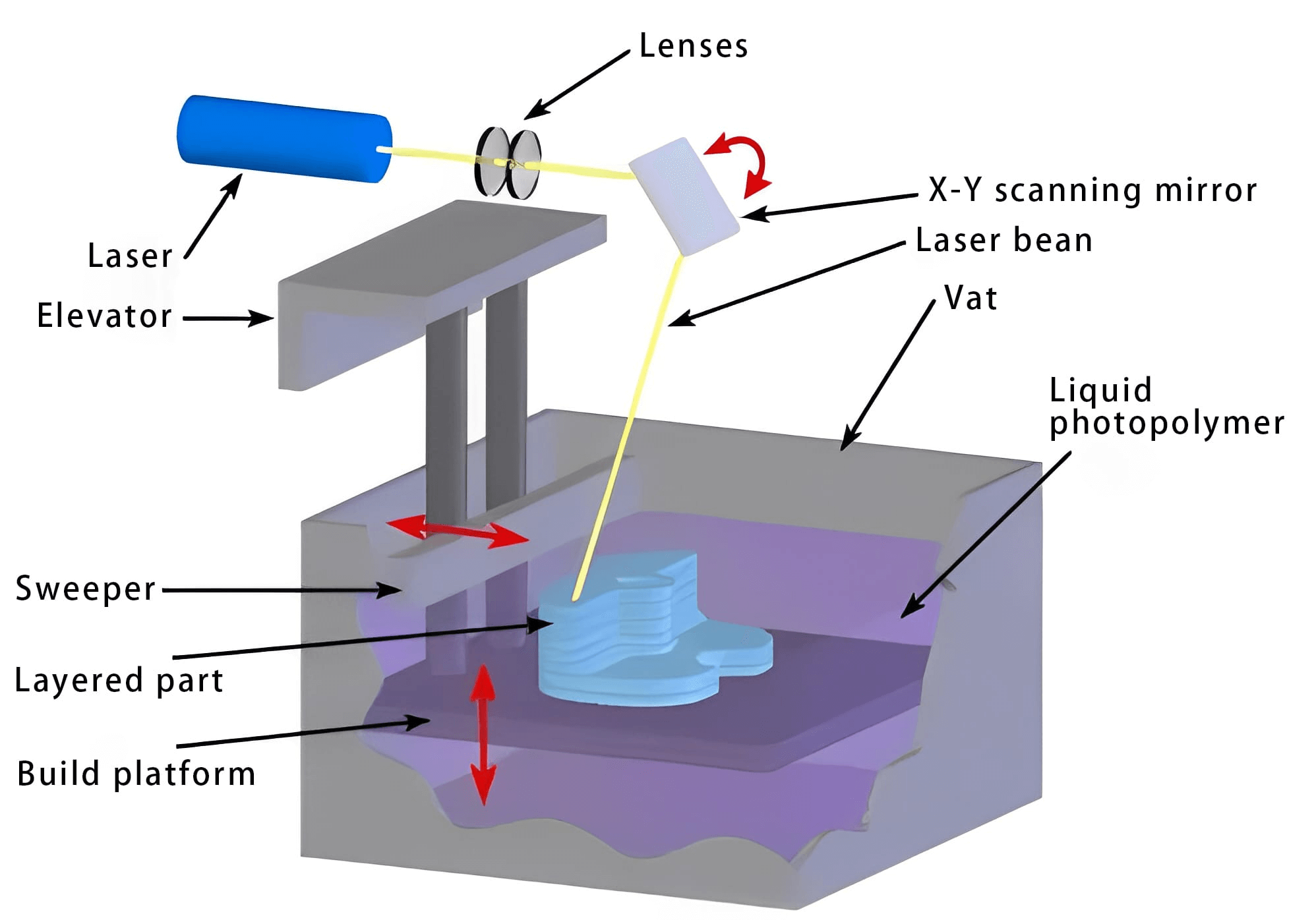

SLA

SLA (Stereolithography) is one of the most popular 3D printing technologies for creating high-precision, clear resin parts. It works by using a UV laser to cure liquid resin layer by layer, building up a part with high accuracy. To get more details about SLA process, read the article: SLA vs. SLM vs. SLS.

Source: custompartnet.com

DLP

DLP (Digital Light Processing) is another highly effective 3D printing technology for printing clear resins. While similar to SLA, DLP uses a digital projector to cure the resin, enabling the printing of an entire layer at once, rather than point by point.

Source: makeagif.com

SLA VS. DLP

SLA offers slightly higher precision and surface smoothness, making it ideal for parts that require high detail and perfect transparency, such as optical components.

DLP, on the other hand, is faster and still provides excellent results for most transparent parts. It's well-suited for applications that need moderate precision but with the advantage of quicker production times, such as small-batch or functional prototyping.

Model Design Tips

Transparent resin printing has stricter design requirements than regular resin printing. Special attention, thus, should be paid to the following aspects when designing the model:

Recommended Wall Thickness: 1-3 mm

Transparent parts need good light transmission. If the wall is too thin, it may affect the optical properties of the final part. If too thick, it can reduce transparency, especially in complex structures where it might scatter light internally.

Avoid Complex Internal Structures

Complex internal structures (such as deep slots, complex cavities, or fine channels) can easily lead to air bubbles or uncured resin, which can negatively affect transparency.

Use Fillets or Chamfers Instead of Sharp Angles

Sharp corners and abrupt changes in geometry not only affect printing precision but also increase printing difficulty. These shapes may cause uneven curing of the resin, which can lead to reduced transparency or surface imperfections.

Avoid Complex Surface Textures

Complex textures can cause uneven light reflection, making transparent parts look blurry or hazy. Even small surface irregularities affect the final appearance.

Post-processings for Clear Resin 3D Printing

After printing transparent parts, standard post-processing steps are typically performed to ensure ideal transparency, surface smoothness, and physical properties, including:

Cleaning: Immerse or scrub the printed part using isopropyl alcohol (IPA) or specialized cleaner to remove uncured resin and ensure a clean surface.

Curing: Expose the part to UV light for a few minutes to further harden the resin and enhance stability and optical quality.

After these default steps, additional post-processing will be done based on customer requirements. The most common post-processing services are painting and dyeing.

Painting | Dyeing |

|---|---|

|

|

Comparison of Clear Resin 3D Printing Service Provider

To help you find the most suitable one when choosing a service provider, we have compared some key clear resin 3D printing service providers around the world in the following aspects for your reference.

Xometry | Hubs | Rapid direct | JLC PCB | 3ERP | Unionfab | PCBWay | |

|---|---|---|---|---|---|---|---|

Technology for Clear Resin |

|

|

|

|

|

DLP |

DLP |

Max Size for | 736x635x533mm | 500x500x500mm | 600x600 x400mm | 780x780x540mm | Not Mention | 800x800 x550mm | 800x800 x600mm |

Shortest |

|

|

|

|

|

|

|

Instant | ✅ | ✅ | ✅ | ✅ | ❌ | ✅ | ✅ |

Trustpilot Score |

Regarding the cost comparison, while most providers in the table offer instant quoting systems, and we could upload the same model to obtain quotes from each, we’ve found that prices vary depending on the part volume. Additionally, extra costs may apply if post-processing is required, so it’s unnecessary to list them here.

However, if you’ve already decided on what you need to print and your other requirements, you can use Unionfab's instant quoting system or those of other providers in the table to compare prices.

To calculate your 3D printing costs anytime in the future, simply bookmark our cost calculator page: https://www.unionfab.com/order#/anonymous_new_shop_quote/?origin=MKblog. It will make things easier next time!

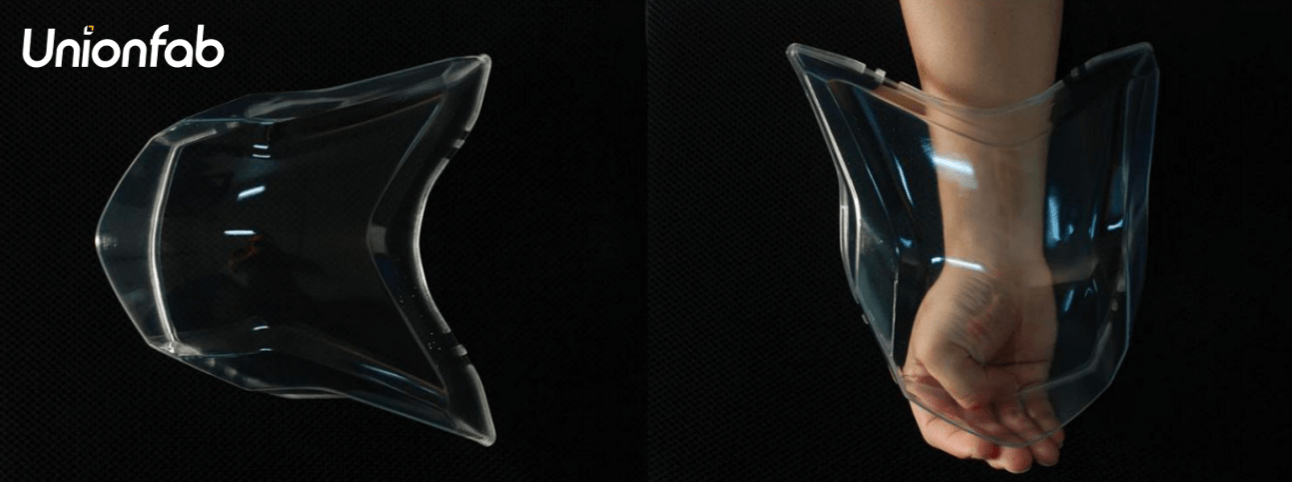

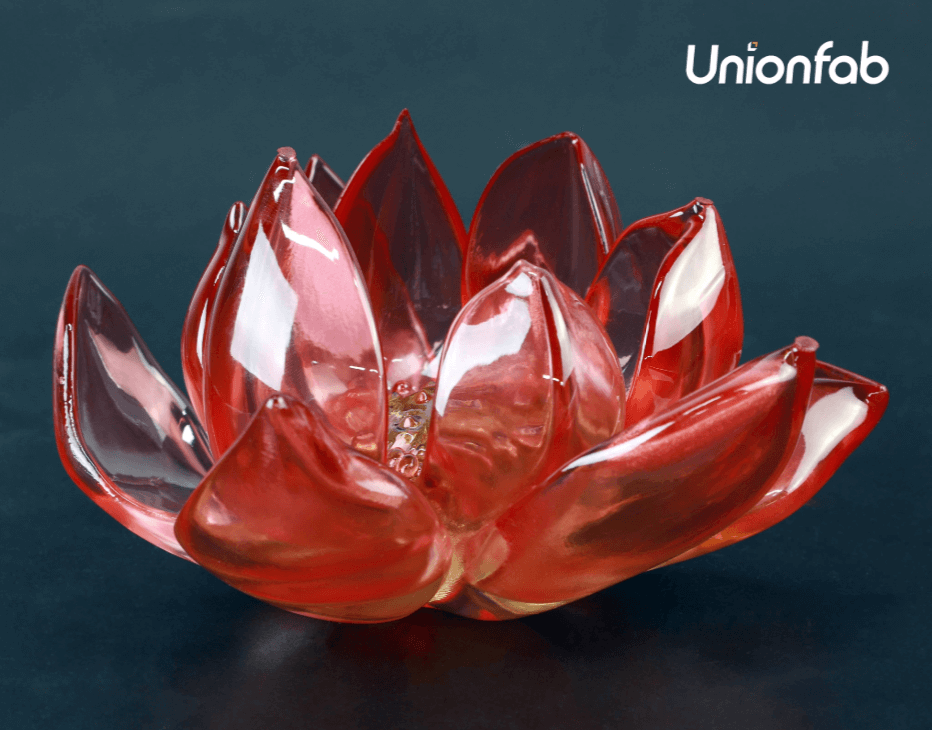

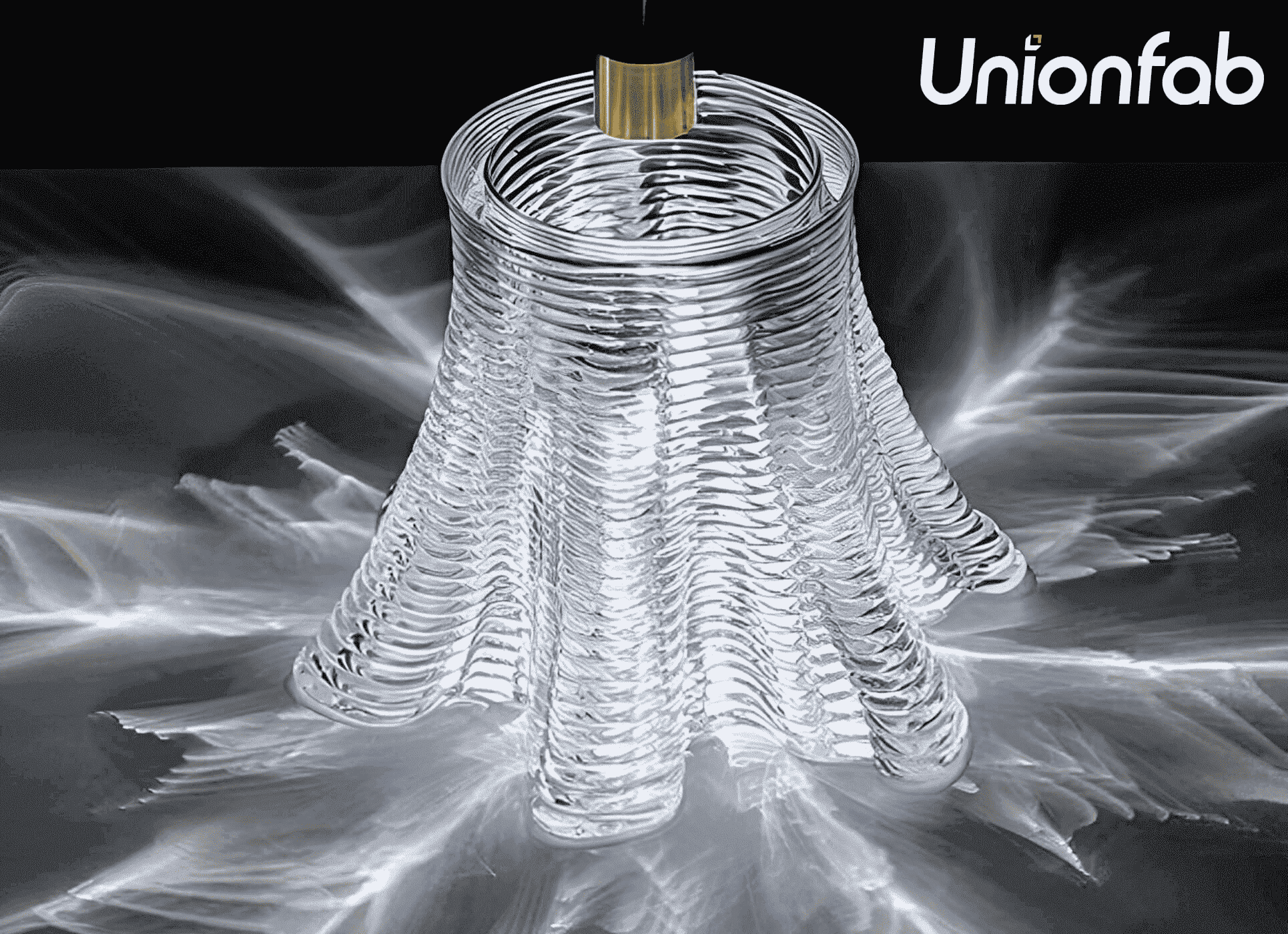

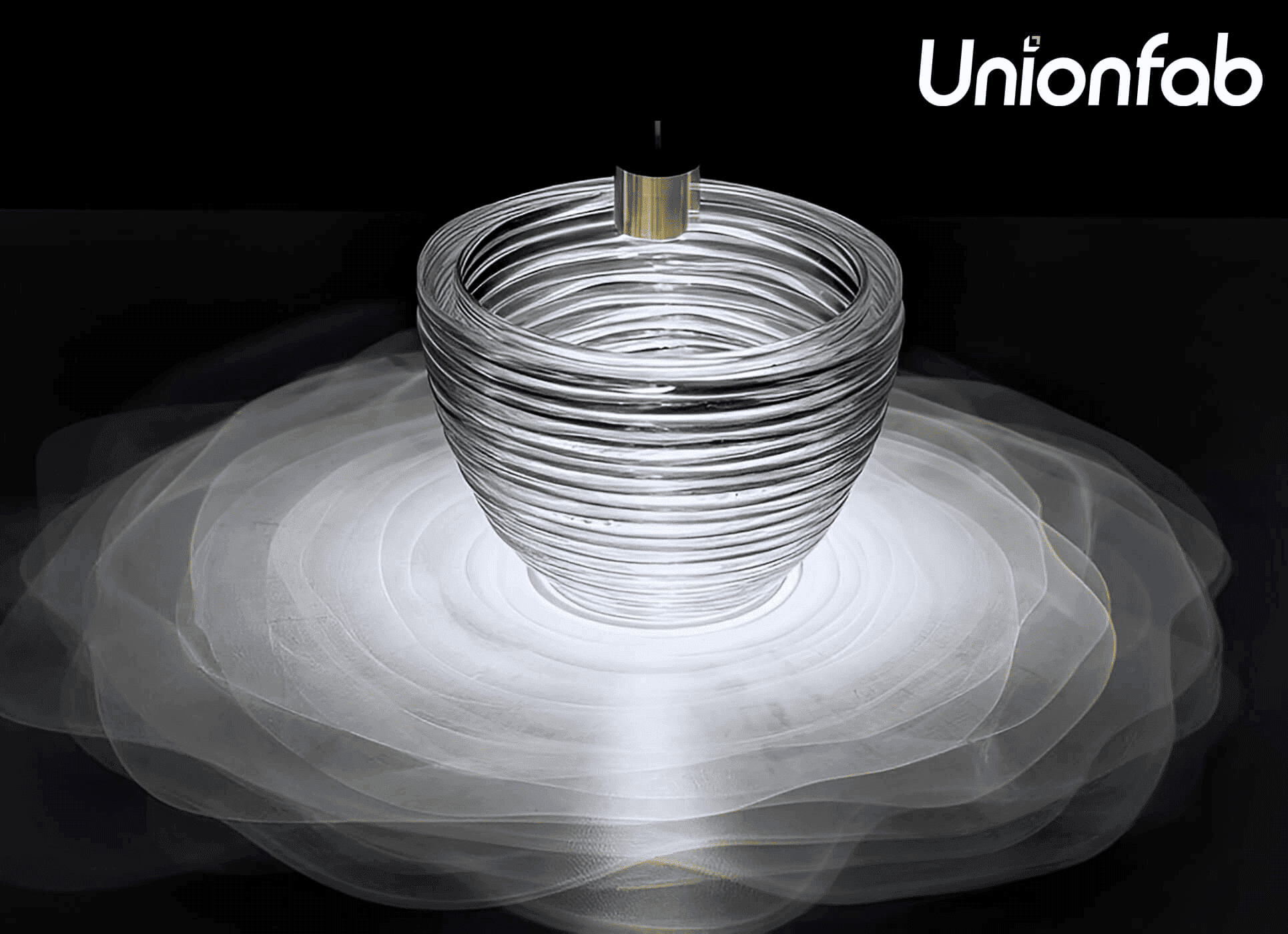

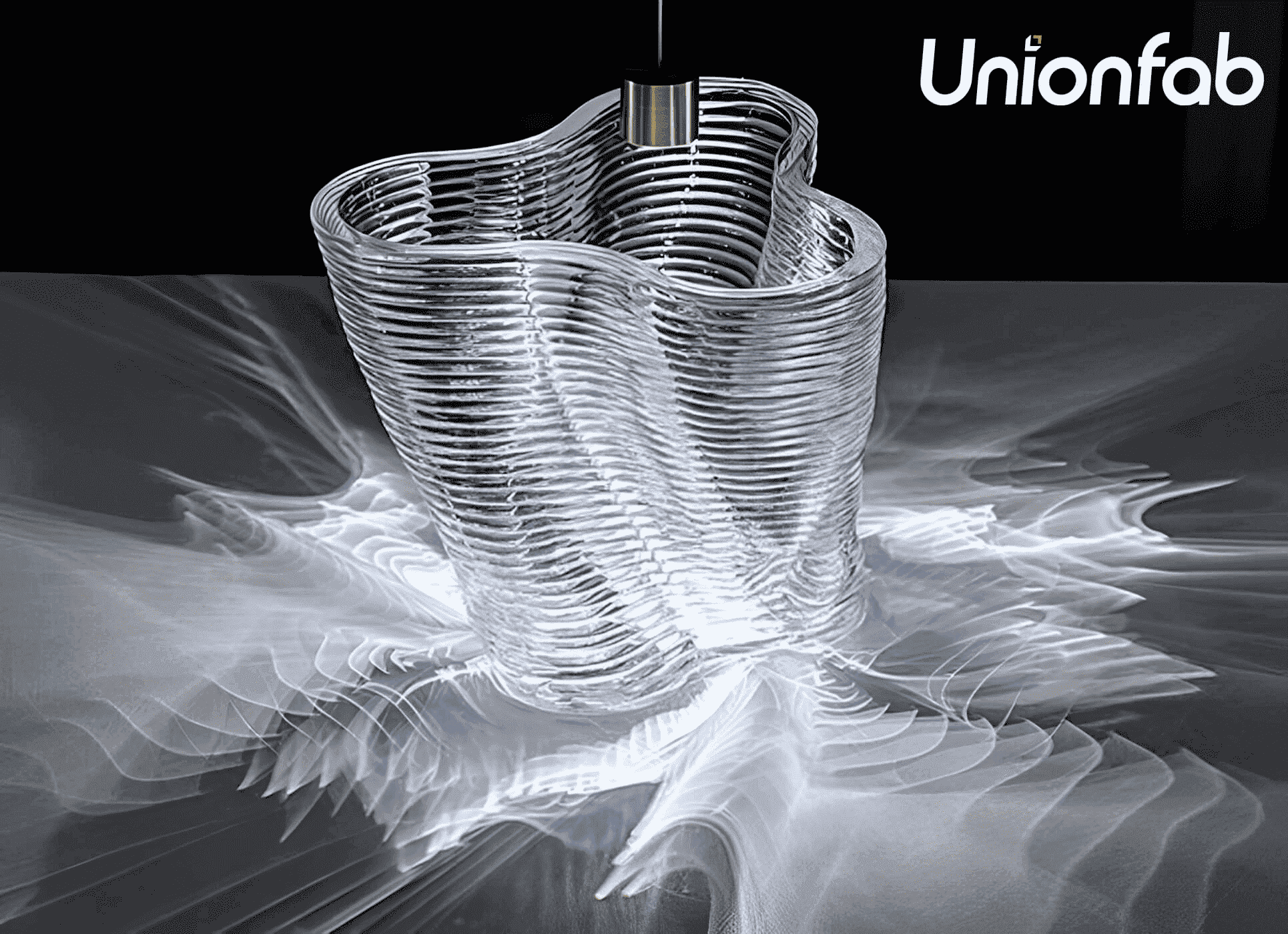

Get High-Quality Clear Resin 3D Printing with Unionfab

Unionfab is China's largest 3D printing manufacturing company. With 20+ years’ experience, 1000+ industrial 3D printers and ISO9001 Certification, Unionfab can offer cost-effective and reliable clear resin 3D printing services.

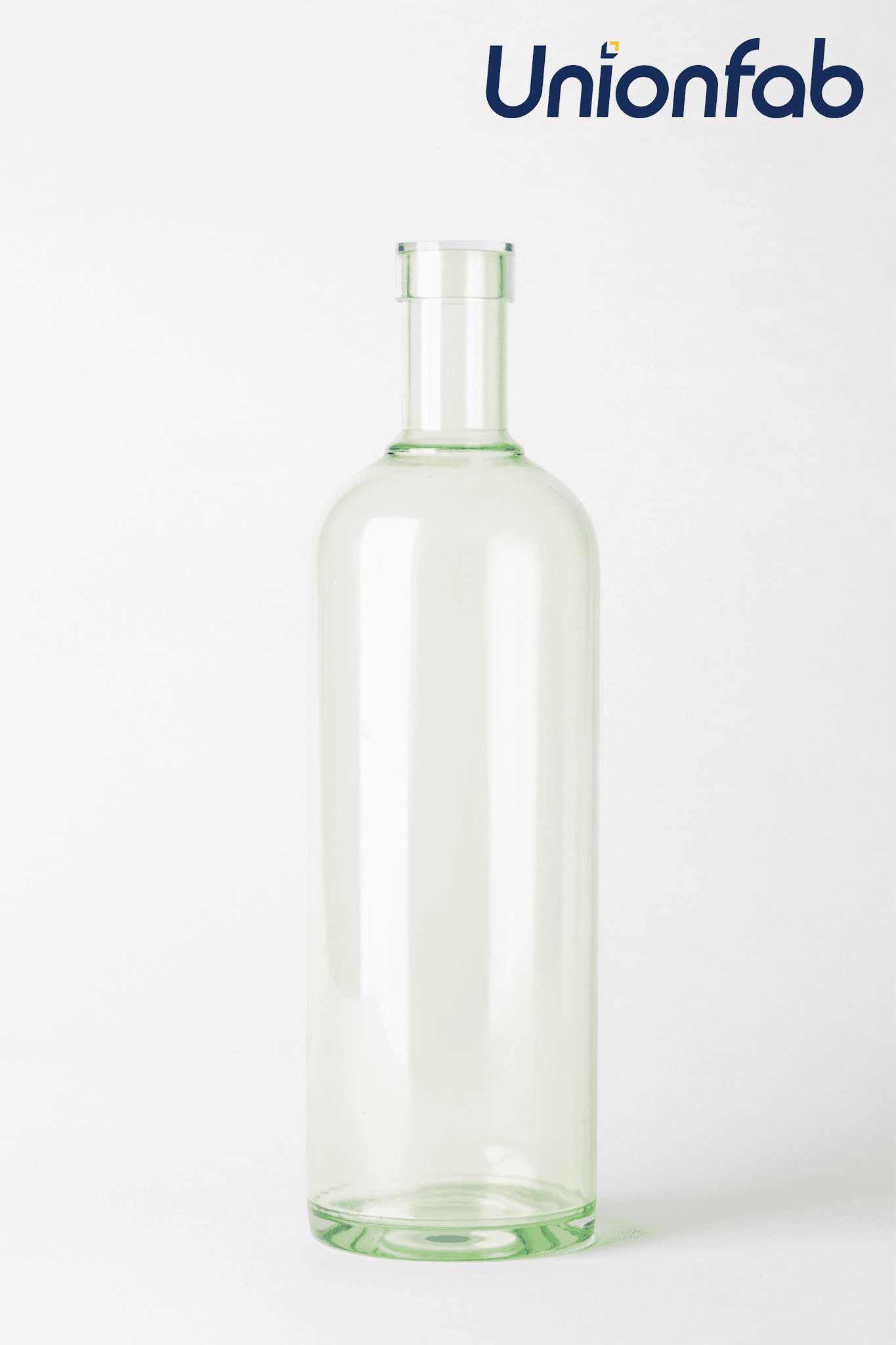

Our clear resin delivers high transparency, low viscosity, and full light transmission for precise, smooth prints. It also ensures excellent strength, toughness, and dimensional stability, with a lifespan of over 6.5 months, perfect for industries like automotive, medical, consumer electronics and more.

Colorless | Colorful |

|---|---|

|

|

|

|

|

|

Alternatives for Clear Resin 3D Printing

In addition to 3D transparent resins, other materials and production methods can also be used to create transparent parts. Below is a comparison of some common materials.

Material | Transparency (Light Transmittance Rate) | Price | Applicable Production Methods | Advantages | Disadvantages |

|---|---|---|---|---|---|

PMMA (Acrylic) | Very High (92%) | Medium | Injection Molding, CNC Machining | High transparency, easy to process, suitable for optical components and display models. | Brittle, poor impact resistance, prone to cracking, not suitable for high-impact applications. |

PC (Polycarbonate) | High (88%) | Higher | Injection Molding, CNC Machining | High impact resistance, good thermal stability, suitable for functional transparent components | Susceptible to scratching, more difficult to process. |

PETG (Polyethylene Terephthalate Glycol) | Medium ( 85%-90%) | Low | Injection Molding, CNC Machining | Good transparency, strong impact resistance, suitable for low-cost transparent parts. | Poorer surface smoothness, suitable for non-critical transparency applications. |

Summary:

PMMA offers the best transparency and is ideal for display models and optical components, but it's brittle and prone to cracking.

PC provides high durability and impact resistance, making it suitable for functional transparent parts that require strength, but its transparency is slightly lower than PMMA, and it's more difficult to process.

PETG is the most cost-effective option and has good impact resistance, making it suitable for applications where high transparency isn't critical, but it offers lower clarity compared to PMMA.

For the alternatives above, Unionfab also provides both CNC machining and Injection molding services, please feel free to contact us if you’re interested.

FAQs

Why is my 3d prints resin mirroring?

Mirroring in resin prints can happen due to:

Incorrect UV exposure: Over-curing or improper exposure settings (too long or too short) can cause uneven curing, leading to a mirror-like surface.

Low-quality resin: Poor resin can result in uneven curing and surface defects.

Environmental factors: Humidity and temperature fluctuations can affect curing, so a controlled environment helps.

How long do resin 3d prints last?

Indoor Storage: Protected from UV light, in a cool and dry environment

Standard resin prints can last 1 to 3 years.

Durable resins can last 3 to 5 years. Outdoor Exposure: Exposed to outdoor conditions, the lifespan is much shorter.

Standard resins can last several months to 1 year

UV-resistant or specialized resins can last 1 to 2 years

Is resin or filament better for 3d printing?

Whether resin or filament (used in FDM printing) is better depends on your specific application and requirements. Here’s a comparison:

Resin (SLA/DLP printing)

Pros:

High precision: Resin printing is known for its exceptional detail and smooth surfaces, ideal for fine details and small parts.

Complex geometries: Can easily print complex shapes and overhangs without the need for support structures.

Better for small models: Ideal for detailed models, such as miniatures, dental prints, and jewelry.

Cons:

Longer print times: Resin printing is generally slower compared to FDM printing.

Post-processing required: Requires cleaning and curing post-printing.

Cost: Resin and resin printers are typically more expensive than filament-based systems.

Health and safety: Resin can be toxic if mishandled, requiring careful handling and protective gear. ⠀

Filament (FDM printing)

Pros:

Lower cost: Filament printers and filament are generally cheaper than resin printers and resins.

Larger prints: FDM printers can handle larger models.

Easier to handle: Filament is safer and easier to store and handle compared to liquid resin.

No post-processing: While minor finishing work may be needed, FDM prints are ready to use after printing.

Cons:

Lower precision: FDM printers tend to have lower resolution compared to resin printers, resulting in rougher surfaces and less fine detail.

Supports: FDM requires support structures for overhangs, which can be difficult to remove. ⠀Which one is better?

Resin is better for high-detail prints (such as miniatures, dental, and jewelry models).

Filament is better for larger, functional parts and for users who need an affordable and easier printing solution for everyday use.

How to paint resin 3d prints?

To paint resin 3D prints and achieve a smooth, durable finish, follow these steps:

Clean the Print:

Use isopropyl alcohol (IPA) to remove residual resin, then dry the print completely. ⠀

Cure the Print:

Ensure the print is fully cured under UV light to avoid smudging or peeling. ⠀

Sanding:

Lightly sand the surface with fine-grit sandpaper (200–400 grit) to smooth imperfections. Wet-sanding can improve the finish. ⠀

Priming:

Apply plastic or resin primer to ensure good paint adhesion. Use spray primer for an even coat.

Painting:

Use acrylic or spray paint, applying thin coats and allowing each layer to dry before the next. ⠀6. Sealing:

Apply a clear coat (matte, satin, or gloss) to protect the paint and add shine. UV-resistant clear coats help prevent fading.

Tips:

Ensure the paint layers are thin to avoid clogging the fine details of your print.

Mask off areas you don’t want to paint (if needed) with masking tape.

By following these steps, you can achieve a professional-looking painted finish for your resin 3D prints.