SLM Explained: What It Is and Why It Matters in Modern Manufacturing

Discover how SLM technology revolutionizes manufacturing with its precise metal 3D printing process, from benefits to industrial applications.

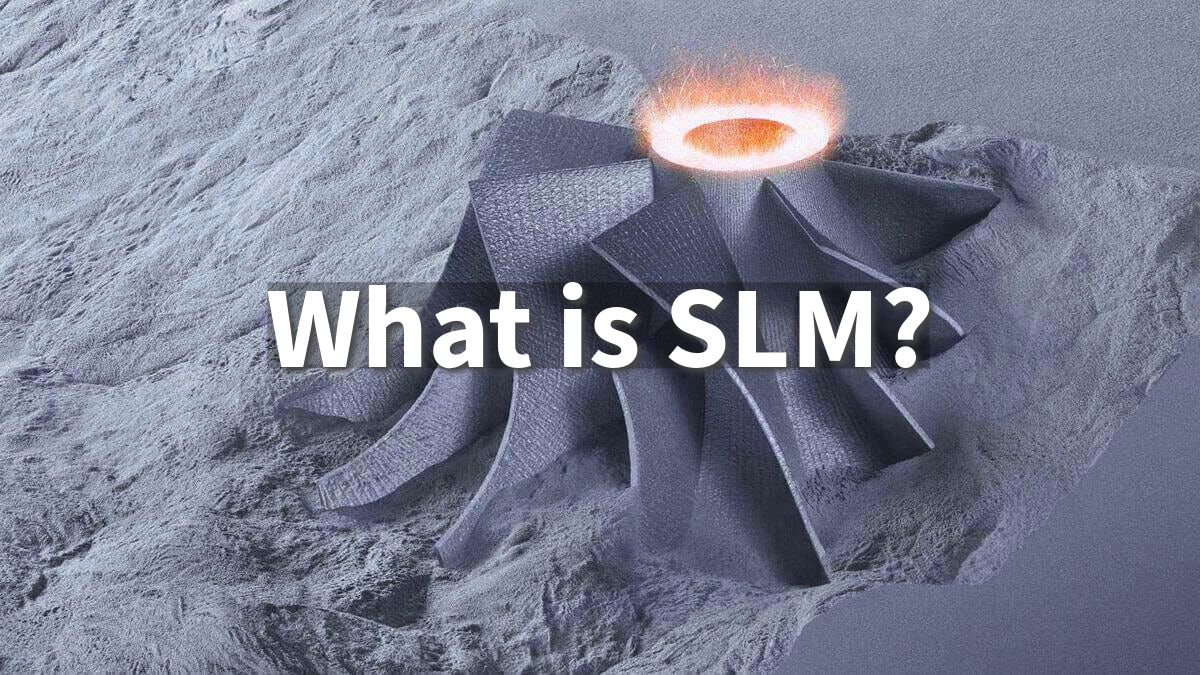

Introduction to SLM

Selective Laser Melting (SLM) is a type of advanced 3D printing that is used to make strong metal parts. It works by using a powerful laser to melt and fuse fine metal powder layer by layer, which creates solid metal pieces. This process helps make parts that are not only strong but also very detailed and customized, which is why SLM is one of the popular methods for metal 3D printing.

SLM is important in modern manufacturing because it can create complex shapes that are hard to make with traditional methods. Industries like aerospace, automotive, and healthcare benefit a lot from SLM because it can make lightweight but strong parts, which helps them innovate and be more efficient.

How SLM Works

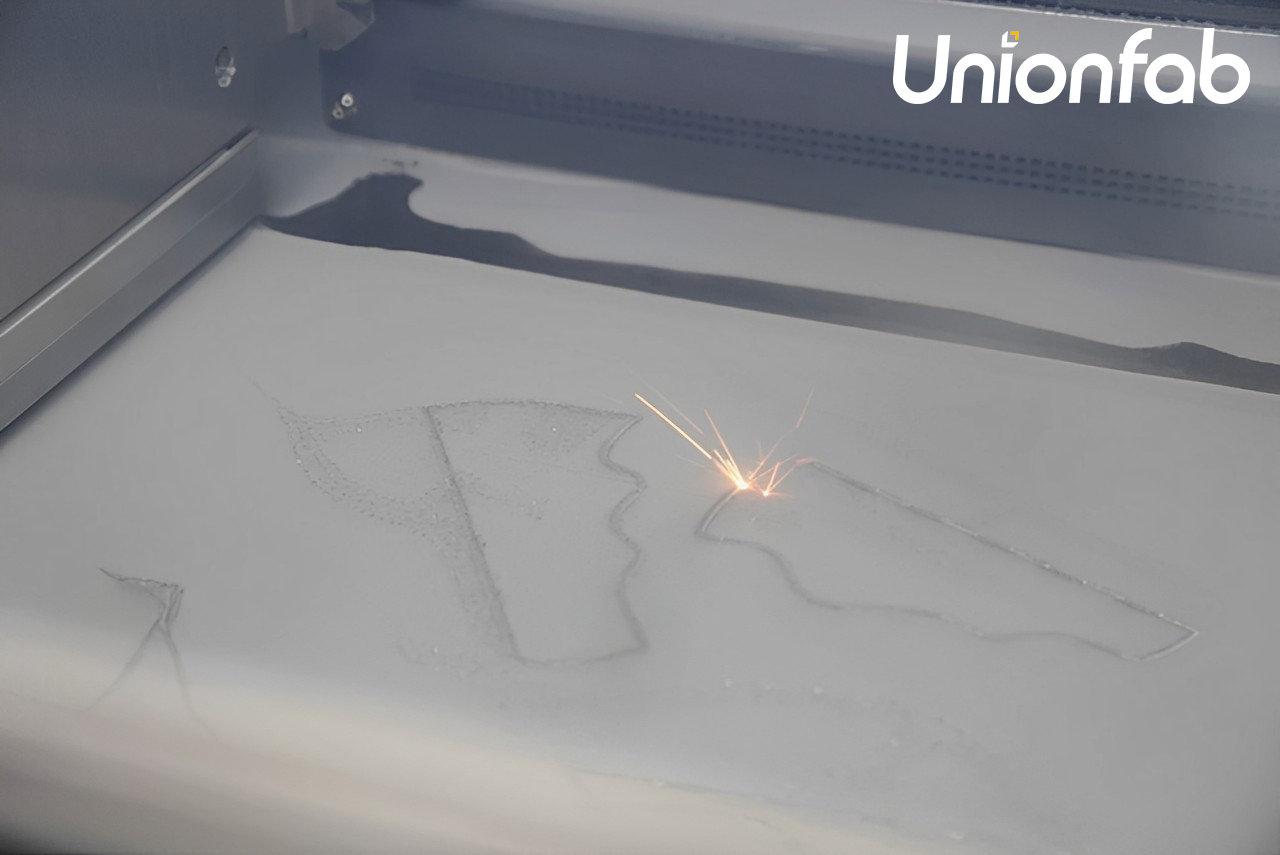

SLM is based on a process called powder bed fusion (PBF), where a laser fuses powdered metal to create solid parts. The process starts by spreading a thin layer of fine metal powder over a platform. A high-powered laser then moves across the powder, melting and fusing the particles in certain areas, based on a digital 3D model of the part.

Source: Unionfab

After each layer is fused, the platform lowers slightly, and a new layer of powder is spread over the previous one. This repeats until the entire part is formed. The main steps in the SLM process are:

Powder Layering: A thin layer of metal powder is spread over the platform.

Laser Fusion: The laser melts the powder based on the part's digital design, fusing the particles together.

Layer Recoating: After each layer is complete, the platform lowers, and a new layer of powder is applied.

Part Building: This process continues until the part is fully built.

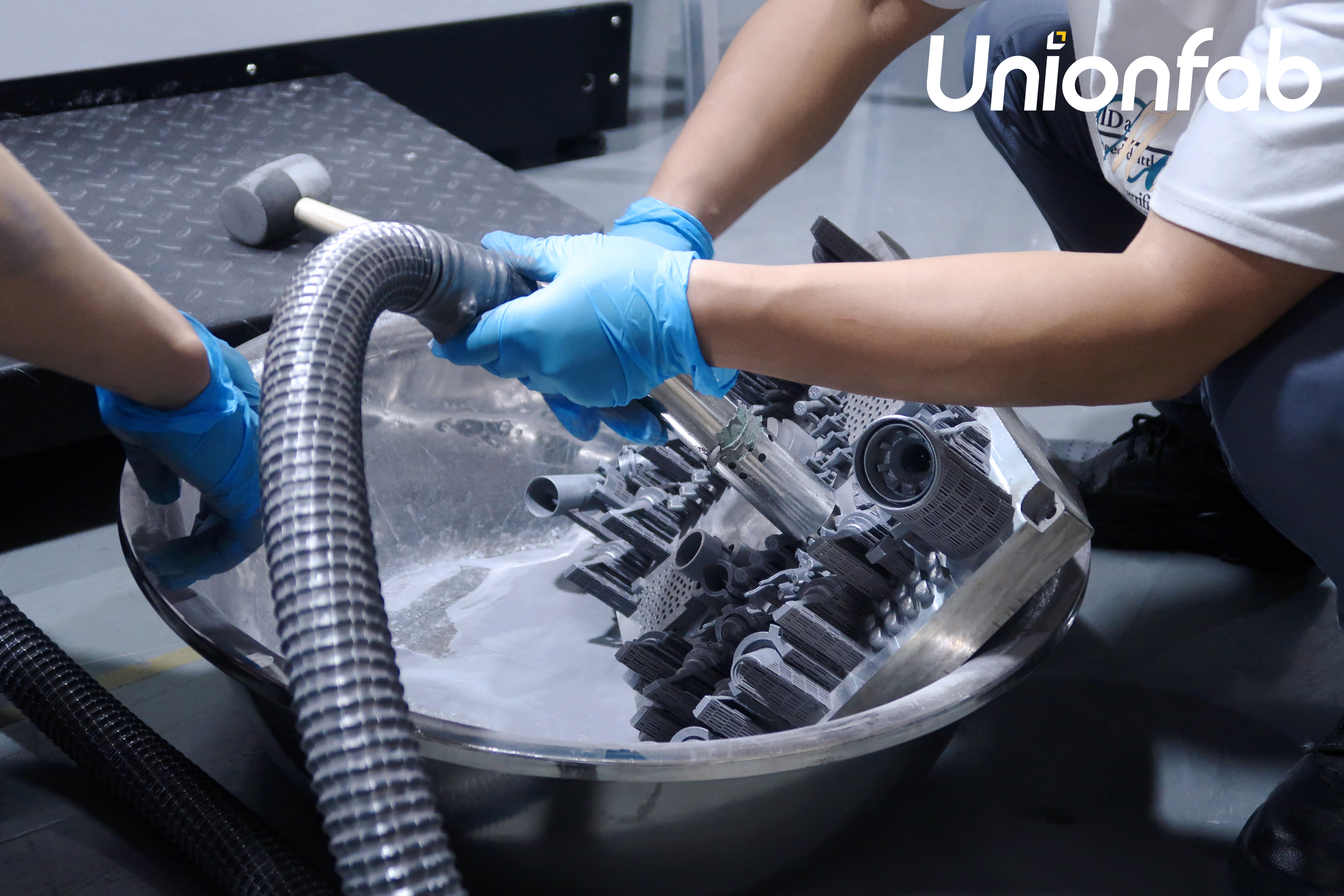

Post-Processing: Once the part is built, it may need extra steps like support removal, heat treatment, or surface finishing to achieve the final quality.

Source: Unionfab

SLM can create complex, fully solid metal parts, which makes it a powerful tool for manufacturers looking to push the limits of design and performance.

Materials Used in SLM

SLM can work with different types of metal, each with its own special qualities that make it good for specific uses. Common materials used in SLM include:

Source: Unionfab

Stainless Steel: Stainless steel is strong and resistant to rust, which makes it great for parts that need to be durable. It is often used in medical, automotive, and consumer products.

Titanium: Titanium is lightweight, strong, and compatible with the human body, making it perfect for aerospace components and medical implants. SLM helps make complex titanium parts that meet strict standards.

Aluminum: Aluminum is popular because it is lightweight and has good thermal and electrical conductivity. It is commonly used in automotive and aerospace applications where reducing weight is important.

These materials are good for SLM because they can be finely powdered and melted to create solid parts. Their properties—such as strength, rust resistance, and lightweight characteristics—make them ideal for demanding uses where traditional manufacturing methods might not work well.

Advantages and Limitations of SLM

SLM offers several benefits that make it useful in modern manufacturing:

Advantages of SLM

Source: Unionfab

High Precision: SLM can make parts with complex shapes and fine details that are hard to achieve with traditional methods.

Material Strength: The parts made with SLM are fully solid and have strength similar to those made with traditional manufacturing methods.

Versatility: SLM can work with a wide range of metals, making it useful for industries like aerospace, medical, and automotive.

Limitations of SLM

High Cost: The equipment and materials used in SLM are expensive, which makes it costly for some uses, especially for small production runs.

Specialized Equipment: SLM needs high-powered lasers, precise control systems, and an inert gas environment, which leads to high operational and maintenance costs.

Material Restrictions: Not all materials are suitable for SLM, which limits its use in some cases.

By understanding both the benefits and the limitations of SLM, manufacturers can decide how to best use this technology for their production needs.

SLM vs. Other Metal 3D Printing Techniques

SLM is one of several metal 3D printing technologies, each with its own unique characteristics. Here is how SLM compares to some other methods:

SLM vs. DMLS (Direct Metal Laser Sintering)

SLM and DMLS are similar, but while SLM fully melts the metal powder, DMLS only partially fuses the powder. This means SLM parts are usually stronger and denser, making SLM better for high-performance applications.

SLM vs. SLA (Stereolithography)

Source: Unionfab

SLA uses a laser to cure liquid resin layer by layer. It is great for creating detailed plastic prototypes but can't match the strength of metal parts made by SLM.

SLM vs. SLS (Selective Laser Sintering)

SLS is similar to SLM but works with plastic powders instead of metal. It is ideal for making functional plastic prototypes but lacks the strength of metal parts from SLM.

SLM vs. Binder Jetting

Binder Jetting uses a binding agent to create parts layer by layer. After building, the part is sintered for strength. Binder Jetting is often faster and cheaper than SLM but doesn't produce parts as strong or dense.

Unique Aspects of SLM

SLM stands out because it can create fully dense metal parts that have properties similar to those made with traditional methods. Its high precision, ability to work with different metals, and ability to create complex shapes make it a popular choice for industries like aerospace, automotive, and medical that need high-quality parts.

Compared to methods that only partially fuse powder, SLM produces stronger parts.

Applications of SLM in Various Industries

SLM is used in many industries, each benefiting from its ability to create high-quality parts:

Source: Unionfab

Aerospace: The aerospace industry uses SLM to make lightweight, strong parts that can handle extreme conditions. Examples include turbine blades, brackets, and fuel nozzles.

Medical: In the medical field, SLM is used to make custom implants and prosthetics that fit each patient. Titanium implants, dental crowns, and orthopedic devices are commonly made with SLM because of their strength and compatibility with the body.

Automotive: The automotive industry uses SLM to make lightweight parts that improve fuel efficiency and performance. Examples include engine parts, transmission components, and customized brackets.

Tooling: SLM is also used to make specialized tools like molds and dies with cooling channels. These tools help improve efficiency in processes like injection molding and die-casting.

SLM's ability to make complex, fully solid metal parts with excellent mechanical properties makes it a valuable tool for industries that need high-quality, customized components. Its applications continue to grow as manufacturers discover new ways to use this technology.

Conclusion

Selective Laser Melting (SLM) is an important part of 3D printing, especially for industries that need strong, precise metal parts. Its ability to create complex, fully solid components makes it a popular choice for aerospace, medical, automotive, and tooling applications. Although SLM is expensive and needs specialized equipment, it stands out because of the quality and precision of the parts it produces.

Businesses can use SLM to improve their products by making complex metal parts that were too hard or costly to make with traditional methods. By understanding what SLM can and cannot do, companies can decide when and how to use this technology to improve their production, grow, and stay competitive in their industries.

Transform Your Manufacturing with SLM at Unionfab

Unlock the full potential of SLM technology for your projects with Unionfab. Whether you’re exploring advanced manufacturing solutions or need precision metal parts, our expertise in Selective Laser Melting can bring your ideas to life.

Contact Unionfab today to learn how SLM can elevate your production capabilities!