Will Galvanized Steel Rust?

Learn if galvanized steel rusts, how it works, the factors affecting corrosion and tips to prevent rust.

What Is Galvanized Steel?

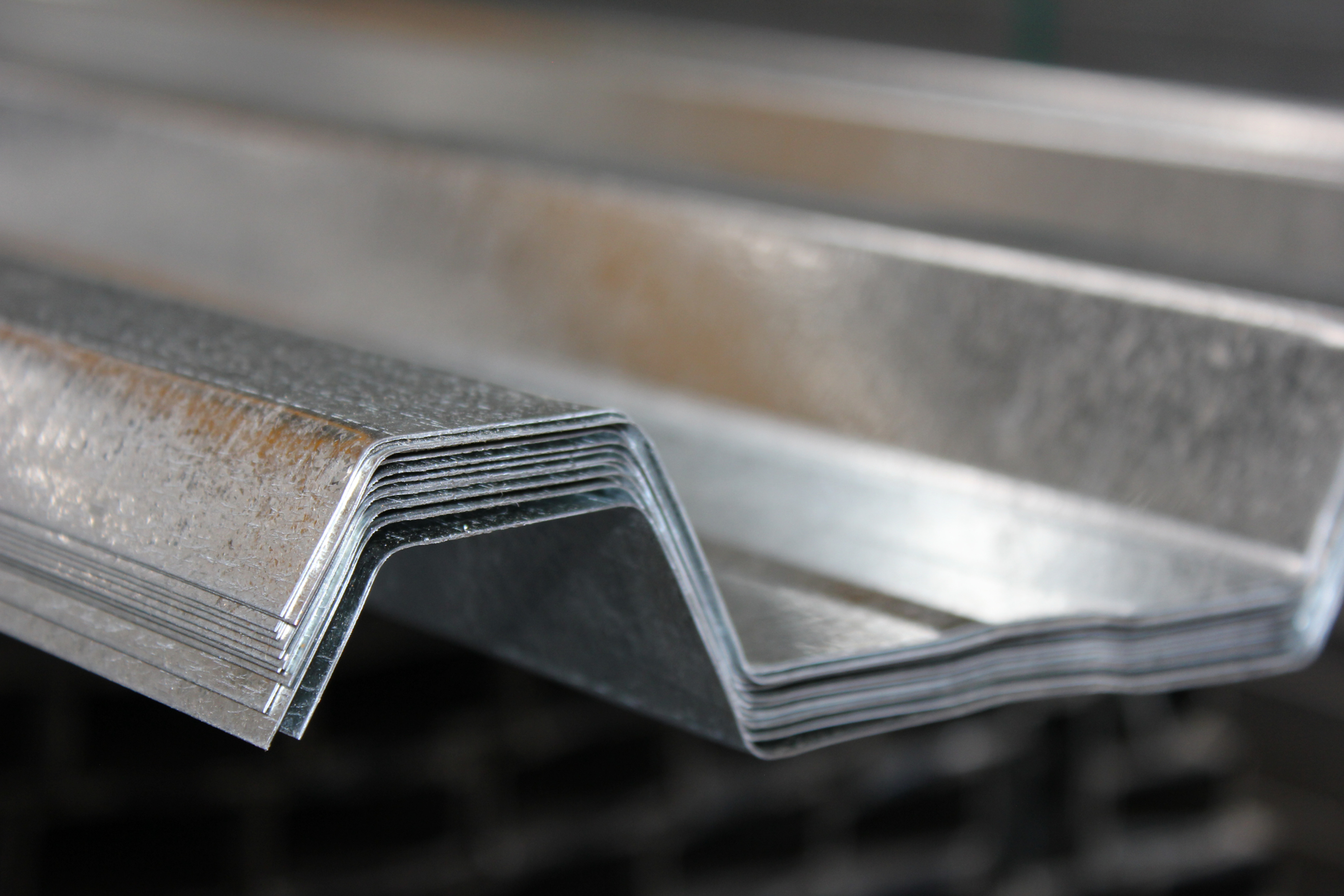

Galvanized steel is a type of steel that has been coated with a zinc layer for corrosion protection. It is a popular metal choice for outdoor structures and products due its corrosion resistance properties.

Source: algoasteel-vaal.com

Galvanized steel is made by hot-dipping or electroplating plain (mild) steel in molten zinc to form a protective coating on the outer surface. The zinc coating acts as a sacrificial barrier, protecting the steel underneath from rusting even in harsh outdoor environments.

Due to its ability to withstand weathering, galvanized steel has become a commonly used building material for fences, pipes, roofing, and other metal constructions.

How Galvanizing Prevents Rust

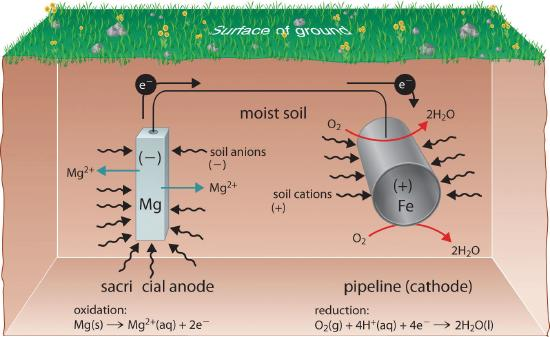

Galvanized steel gets its rust protection from the zinc layer.

Regular steel rusts when oxygen and water in the air interact with the iron in the metal. But the zinc coating helps react with oxygen and water instead of the iron underneath. That's because zinc is more “easily affected” than iron.

Source: zinoglobal.com

If a scratch exposes some steel, zinc atoms will quickly replace the iron atoms and react with oxygen before the iron can start rusting. This “zinc sacrifice” keeps protecting the steel core.

The zinc reaction with oxygen is stronger than the iron reaction. So zinc takes the hit from oxygen so the steel stays safe from rust. This zinc barrier is why galvanized steel can stay rust-free much longer than bare steel exposed to the weather. The zinc saves the steel through its chemical reaction.

Will Galvanized Steel Rust?

Yes! The galvanized steel rusts.

While the zinc coating on galvanized steel provides excellent protection against rust, there are some conditions that may allow corrosion to eventually occur.

Source: dwellinspectaz.com

Heavy damage or wear that completely removes the zinc layer:

If the zinc coating is worn away through years of abrasion and scrapes, it will no longer be able to protect the underlying steel. This exposes the reactive iron to rust situations such as:

Cut edges: Areas where galvanized steel has been cut, such as the ends of pipes or fencing, will not have a zinc coating. Without protection, rust can form on these raw edges.

Harsh environments: Very acidic or saltwater-heavy settings may cause the zinc to corrode faster than normal. This could break down the barrier sooner and expose steel.

Production flaws: On rare occasions, an imperfect or discontinuous zinc coating during manufacturing fails to completely seal out oxygen and moisture.

Improper maintenance: Not taking measures like repainting worn areas can reduce the service life expectancy.

Galvanized steel is usually very good at stopping rust, but sometimes the zinc coating can wear off or get damaged. If this happens, the steel underneath can start to rust, especially if it’s in a bad environment. Over many years, this can cause problems.

With careful handling and recoating of damaged sections, rusting can usually be prevented.

Common Causes of Rust in Galvanized Steel

There are a few key factors that can potentially lead to corrosion in galvanized steel over long periods of exposure:

Scratching and Abrasion - Surface damage from scraping, abrasive materials, or impacts can wear away the protective zinc layer. This exposes the underlying steel to oxidation.

Severe Environments - Harsh, corrosive locations like coastal areas with salt air/water or polluted industrial settings may cause faster zinc degradation. Acids can also damage the coating.

Weathering Effects - Prolonged sun exposure and rain/snow can weaken the zinc's integrity as it breaks down bit by bit over 20+ years outdoors.

Old/Aged Materials - After several decades, the zinc may gradually erode away in some spots, allowing rust to develop deep in the steel substrate.

Assembly Processes - Drilling, cutting, welding operations may create bare steel fringes prone to corrosion initiation.

In all cases, the zinc's ability to shield steel depends on maintaining a solid barrier.If galvanized steel is used for a very long time or in a really tough place, the protective coating can start to wear away. When this happens, the steel can rust, especially if it’s not covered anymore.

Proper maintenance helps maximize galvanized materials’ longevity.

How to Prevent Rust on Galvanized Steel

Regular Maintenance: Look for scratches or worn spots on your galvanized things. If you find any, fix them by sanding and painting with a special kind of paint.

Avoid Harsh Chemicals: Galvanized steel doesn't like strong acids, bases, or salts. If you use these on your galvanized things, rinse them off with water.

Apply Protective Coatings: For things that get used a lot, put on an extra layer of paint, varnish, or sealant to protect it.

Source: mkr-metzger.de

Proper Storage: If you keep your galvanized things outside, try to keep them dry. If you keep them inside, make sure they're in a dry place.

CNC and 3D Printing Projects: When you work with galvanized steel, be gentle. Use tape or grease to cover any cuts or scratches.If you take good care of galvanized steel, it can last for many years and still be protected from rust.

Conclusion

In summary, galvanized steel gets its corrosion resistant properties from the zinc coating applied to the base steel.

Even though zinc helps protect steel from rust, factors like scratches, wear and tear, bad weather, and getting old can damage the zinc coating over time.

Checking on your galvanized steel things and taking care of them can help stop them from rusting, even in bad weather.

Interested in Using Galvanized Steel for Your Next Project?

Whether you're in need of 3D printing, CNC machining or finishing services, Unionfab, a 3d-printing expert with a diverse selection of materials, fast turnaround times, and cost-effective solutions ensures high-quality results.

Contact us right away for a free consultation or click the banner below to get a free quote, thus bringing your ideas to life!

FAQs

Can I 3D print with galvanized steel?

While 3D printing with galvanized steel directly isn’t common, it’s often used in CNC machining or post-processing for 3D printed metal parts.

How can I repair rust on galvanized steel?

You can repair rusted areas by cleaning the surface and applying a zinc-rich paint or cold galvanizing compound to restore protection.