3D Printing Threads: All You Should Know

The guide covers everything you should know about 3D printing threads, including common thread types, best practices, tips, and tricks to get perfect results.

Introduction

3D printing threads can add functionality and strength to printed parts. Whether you need to assemble multiple components, attach hardware, or simply improve a design, understanding how to 3d-print reliable threads is important.

This guide provides best practices for successfully printing common thread types with precision and durability.

What are 3D Printing Threads?

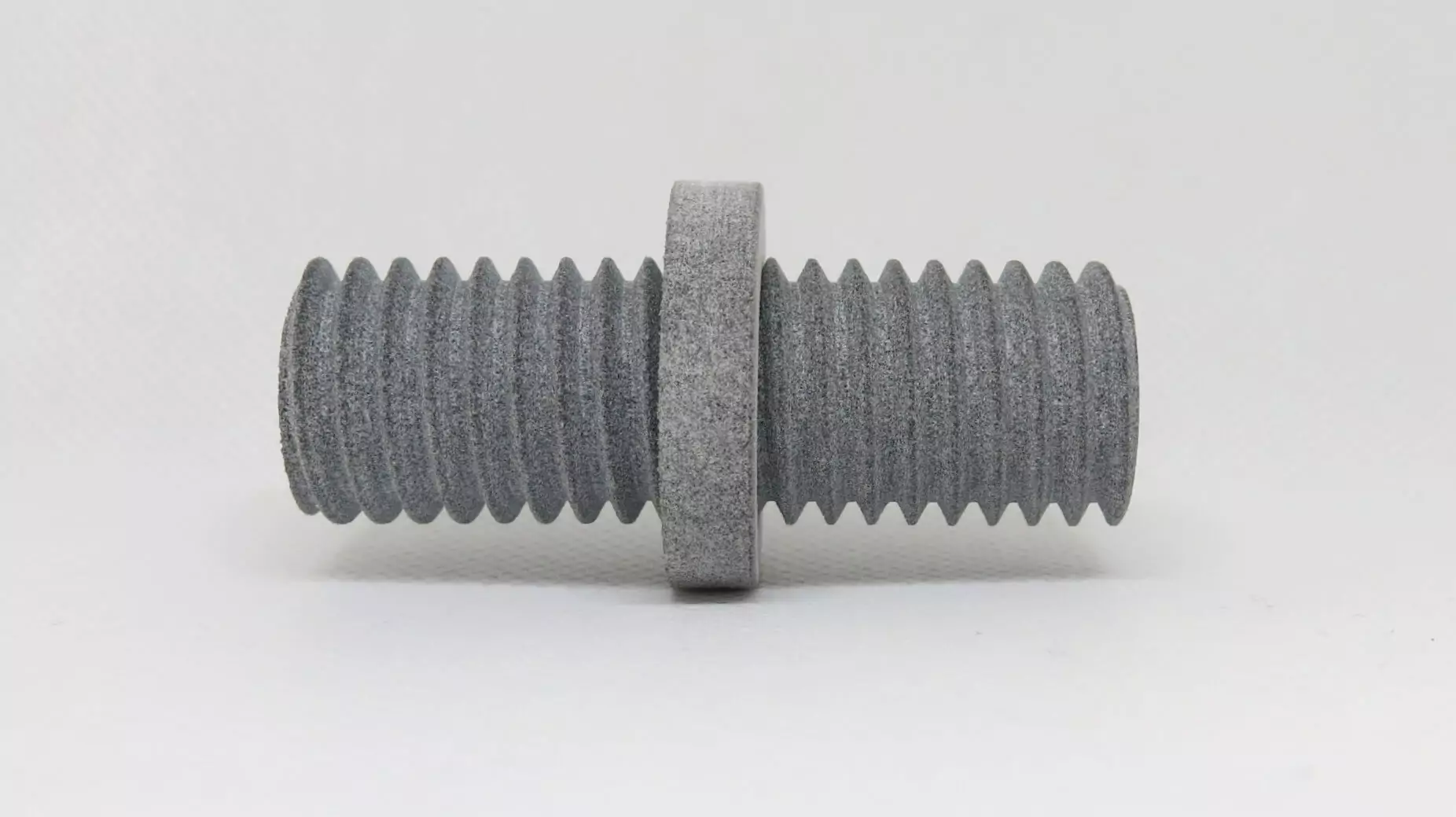

3D printing threads are helical ridges or grooves added to a part during printing. They allow components to be screwed together using bolts, nuts, fasteners, and more.

Source: sculpteo.com

How do they work?

During printing, the hot end extrudes thin layers of plastic in a spiral pattern to form each thread layer by layer. Multiple threads are stacked to build up the 3D helical shape.

Proper settings ensure each layer bonds seamlessly for a smooth, accurate thread. Here’s a breakdown of how 3D printing threads work:

Step1: Design in CAD

Create the thread design (internal or external) using CAD software.

Define thread parameters (diameter, pitch) or use a thread generator.

Step2: Export & Slice

Export the design as an STL file.

Use slicing software to adjust settings (low layer height & slow print speed) and apply support material for overhangs.

Step3: Choose Filament

Use PLA for easy prints or ABS/PETG for stronger, more durable threads.

Step4: Print

Monitor the print for accuracy and layer alignment, especially for complex or fine threads.

Step5: Post-Processing

Remove support material and smooth threads with light sanding.

Optionally, tap or die the threads for a smoother finish.

Step6: Test & Adjust

Test the fit with matching parts. Adjust the design or print settings if necessary.

Types of Threads in 3D Printing

When selecting materials for 3D printed threads, different filament types have unique properties that affect their performance and suitability for various applications. Here’s an overview of some common materials used for 3D printed threads:

Material | Key Feature | Thread Performance | Printing Recommendation |

|---|---|---|---|

Low warping during printing | Threads can be brittle | Print slowly at higher temperatures for stronger layer adhesion | |

Impact-resistant | Threads are strong but prone to warping | Use an enclosure to prevent warping; print at high temperatures | |

Flexible and doesn’t shatter | Good for vibration-prone parts, no support needed for threads | Adjust temperature and speed for accurate threads | |

Nylon | Durable, heat and chemical resistant | Suitable for self-tapping threads, very strong | Print hot and slow to minimize layer separation and ensure reliable threads |

Benefits of 3D Printing Threads

Customization: Create threads in any size or shape for specific applications, offering flexibility and unique designs.

Rapid Prototyping: Quickly produce threaded prototypes, test them, and refine them without expensive tooling.

Cost-Effective: 3D printing eliminates the need for costly tools like taps and dies, reducing expenses in both prototyping and small-batch production.

On-Demand Production: Print threaded parts as needed, minimizing inventory costs and storage space.

Integration with Complex Designs: Incorporate threaded parts directly into complex 3D models, reducing assembly time and effort.

Common Challenges and Solutions

Challenge Type | Challenge Description | Solution |

|---|---|---|

Thread Accuracy | Threads may not fit correctly. | Adjust the design in CAD and fine-tune print settings for better precision. |

Layer Misalignment | Misaligned layers weaken threads. | Slow down the print speed and ensure printer calibration. |

Thread Strength | Threads may be weak. | Use stronger filaments or insert metal thread inserts. |

Overhangs & Supports | Threads with overhangs need support, causing rough edges. | Use supports and smooth threads post-printing. |

Tolerance Issues | Incorrect tolerances cause poor fits. | Adjust thread clearance in CAD and print test pieces. |

Warping/Shrinking | Warping distorts thread shape. | Use a heated bed, control ambient temperature, and print with proper cooling. |

Essential Settings for 3D-Printed Threads

Best Filament Types for Strong and Durable Threads

PLA: Good for prototyping and decorative pieces, but tends to be brittle, making it less ideal for high-stress or functional threaded parts.

PETG: Stronger and more flexible than PLA, PETG is a great choice for durable threads that need to withstand moderate stress. It’s also more resistant to impact and can handle higher temperatures.

ABS: Known for its toughness and heat resistance, ABS is ideal for creating strong, long-lasting threads, especially in functional parts that require durability and wear resistance.

Optimizing Slicer Settings for Thread Accuracy

Layer Height: Use a lower layer height (e.g., 0.1mm or less) to capture the fine details of threads. This helps ensure smoother, more accurate thread geometry.

Extrusion Multiplier: Adjust the extrusion multiplier (also called flow rate) to avoid over-extrusion, which can cause threads to be too tight. A lower multiplier will yield more precise threads.

Temperature: Set the print temperature based on the filament type. For example, printing PETG or ABS requires higher temperatures than PLA to ensure strong layer bonding without causing warping.

Post-Processing Techniques to Improve Fit and Finish

Sanding: Lightly sand the threads to remove small imperfections and smooth out any rough edges left after printing. This will help improve fit, especially for finer threads.

Smoothing: Use methods like acetone vapor smoothing (for ABS) to further refine the surface, making threads more precise and easier to use.

Tapping: For internal threads, using a thread tap after printing can clean up and ensure proper alignment, especially if there are any imperfections from the print.

How to Choose the Right Thread for Your Project?

Factors to Consider

Print Quality: If your printer is capable of high-resolution printing, you can design and print more intricate, precise threads. For lower-end printers, consider simpler thread designs.

Strength and Durability: For parts that need to withstand significant stress, choose strong materials (like ABS or reinforced filaments) and design threads that are wide enough to distribute the load evenly.

Cost: Filament choice affects cost. PLA is affordable for prototypes, but for functional parts requiring durability, investing in PETG or ABS may be worth the additional expense.

Tips for Selecting the Best Thread for Different Applications

Prototypes: PLA or PETG is ideal for testing fit and function, as they are easy to print and reasonably strong.

Functional Parts: Use ABS or other high-strength materials for functional parts that will be under mechanical stress. Metal inserts may be a better option for load-bearing threads.

Toys and Decorative Items: PLA is sufficient for non-functional or low-load applications, such as toys or decorative pieces that only need to look the part.

Real-Life Applications of 3D Printed Threads

Industries Benefiting from 3D-Printed Threads

Automotive: 3D printed threads are used in automotive prototyping for engine components, fasteners, and mounting solutions.

Sourcez: amfg.ai

Electronics: Threaded parts are commonly used for securing electronic components, such as enclosures, mounts, and connectors.

DIY & Makers: Hobbyists often 3D print threaded parts for custom builds, home repairs, or experimental designs, allowing for quick, cheap, and customizable solutions.

Examples of Successful 3D Printed Threaded Parts

Bolts and Nuts: Custom sizes and shapes are often needed for specific builds or machines. 3D printing allows for fast, on-demand production of these parts.

Caps and Lids: Custom containers with screw-on lids are popular 3d-printed projects that benefit from threads.

Connectors: Threaded connectors for pipes, tubes, and other parts are often 3D printed for prototypes or small production runs in various industries.

Conclusion

In conclusion, 3D printing threads can significantly expand the functionality and versatility of your projects.

By understanding the essential tools, filament types, and slicer settings, you can produce high-quality threads suitable for various applications—from prototypes to functional parts.

If you're an industrial designer or a DIY hobbyist in need of 3d-printed threads, get in touch with Unionfab now! Beyond 3d-printing threads, Unionfab provides a wide range of manufacturing services, including CNC Machining, Casting, and Injection Molding, catering to rapid prototyping and on-demand production.

With Unionfab, you can bring your threaded designs to life! Feel free to CONTACT US!