Etching Metal: Techniques, Tips, and Tools

With this comprehensive guide, from laser etching to working with aluminum and stainless steel, find out everything you need to know.

Introduction

Metal etching is a process that allows permanent designs and patterns to be added to metal surfaces.

By using tools like lasers, etchant chemicals, or even homemade methods, the outer layers of metal can be removed to reveal lighter or contrasting layers below. This gives metals an artistic or customized look.

In this guide, we will focus on laser etching as a method for adding designs to aluminum and stainless steel surfaces.

What is Metal Etching?

Metal etching is a process that removes part of the surface of a metal to create a design. There are a few main methods used:

Laser Etching

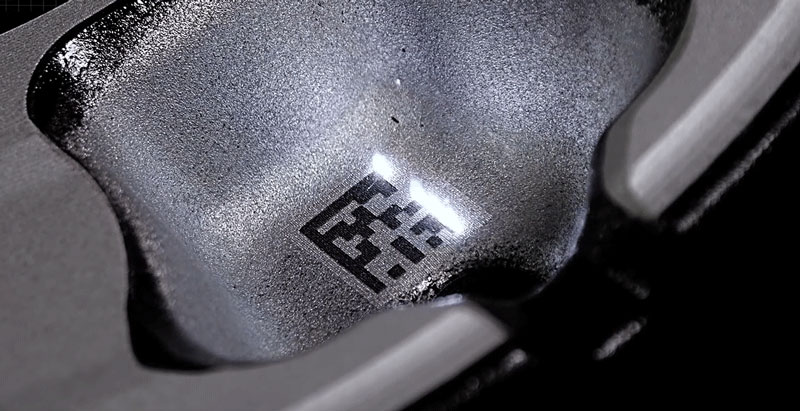

Laser etching uses a concentrated light beam, like from a laser engraver or cutter, to precisely remove tiny amounts of metal.

The laser heats and vaporizes thin layers to reveal a pattern. Laser etching works on most all metals and gives sharp edges ideal for finer details.

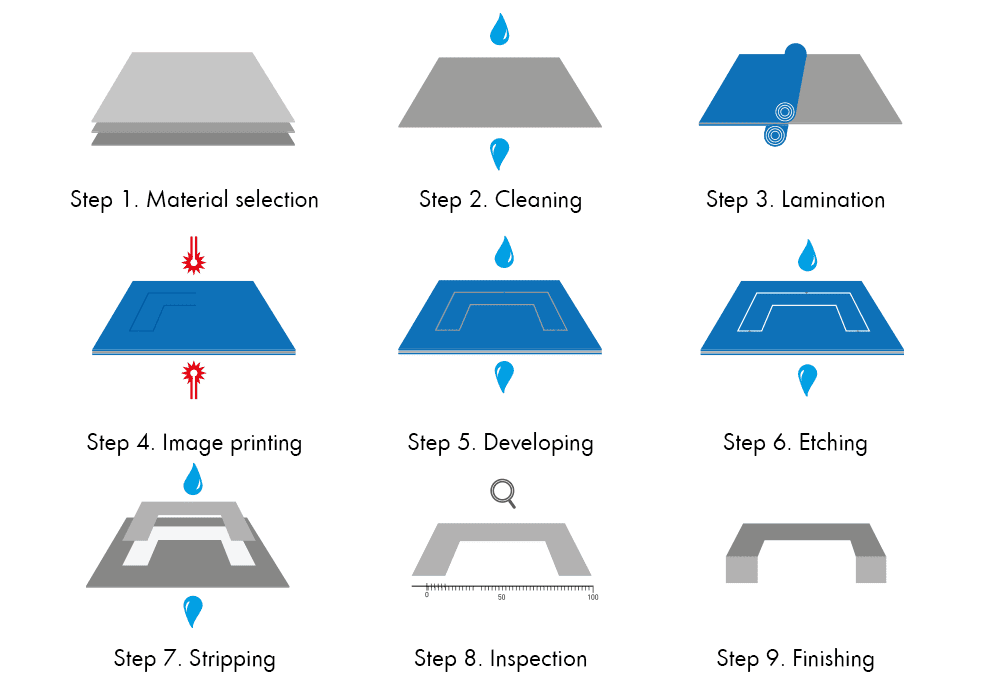

Chemical Etching

With chemical etching, the metal is submerged in an acid or alkaline solution that eats away unwanted metal.

Different solutions etch at varied rates, allowing for textures. It is best for softer metals like aluminum but can use harsh chemicals.

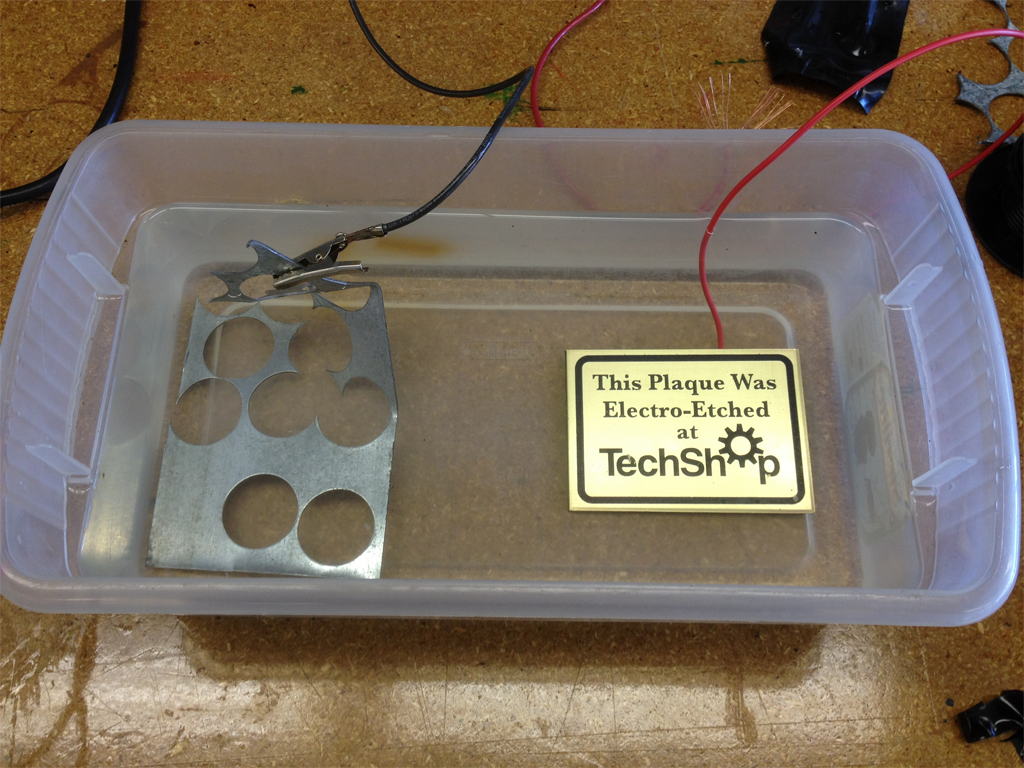

Electro-Etching

An electric current passes through an acid solution with the metal workpiece, chemical reactions remove surface metal where an etching "resist" is not applied. Electro-etching results in consistent depth but complex masks are required.

Mechanical Etching

Techniques like wire brushing or sandblasting use abrasives to mechanically scrub away the metal surface for a weathered look. It is a basic method often combined with other etching.

Laser Etching on Metal

Laser etching uses a high-powered laser beam to carefully remove thin layers of metal.

The laser engraver or cutter precisely directs extremely focused light that heats targeted areas, turning the metal surface into gas without heating surrounding material.

How it Works:

A digital design is uploaded to laser engraving software

The laser beam rapidly scans the metal surface following the design lines

Where the beam hits, it evaporates tiny amounts of metal in tiny pits

Repeating many times creates crisp, detailed etched patterns

Some key advantages of laser etching include:

Precision: Lasers allow for etching extremely fine details down to a few thousandths of an inch wide. This precision is well-suited for small lettering or intricate logos.

Versatility: Nearly all metals can be laser etched, including aluminum, stainless steel, brass, and copper. Complex etching designs with both lines and textures are achievable.

Controlled Process: Laser settings like speed, power, and frequency are digitally controlled for consistency. No messy chemicals and little-to-no surface preparation are required.

Sharp Edges: Since the metal is vaporized rather than scraped away, laser etching leaves clean, well-defined edges that will not fade or wear easily over time.

This precise technique allows for engraving high-quality personalized designs safely and cleanly on metal surfaces.

Etching Aluminum

Aluminum is a versatile metal that is well-suited for etching thanks to its properties:

Properties of Aluminum

Aluminum is lightweight, corrosion-resistant, and accepts etching deeply. It comes in many grades for different strengths and finishes.

How to Etch Aluminum

Laser etching works very well on aluminum, as does chemical etching using solutions like sodium hydroxide. Mechanical methods like sandblasting also suit aluminum's softness.

Etching Tools

For laser etching aluminum, most desktop laser engraving machines effectively remove its surface. Chemical etching requires a non-reactive container, ventilation, and personal protective equipment. Simple mechanical etching can use steel wool or an engraving tool.

Applications of Etched Aluminum

Designs can be etched on aluminum for ID tags, trophies, artwork, or machinery labels. Examples include names or graphics on water bottles, school wall plaques, or astronomy club badges. Engraved science awards demonstrate achievements clearly for long-term display.

With practice following safety procedures, etching transforms the aluminum material into visually appealing personalized creations.

Etching Stainless Steel

Stainless steel has earned its name from its corrosion resistance. Some unique properties of this metal include:

Properties of Stainless Steel

Stainless steel is very durable and does not rust or stain easily. However, its surface is tougher than aluminum so it requires special etching techniques.

How to Etch Stainless Steel

Laser etching works very well, however the laser must be more powerful and move at slower speeds. Ferric chloride (FeCl3) chemical etching also works by dissolving the steel surface chemically.

Etching Tools

A high-powered CO2 or fiber laser engraver can remove stainless steel. For chemical etching, ferric chloride liquid, a non-reactive container, ventilation and protective equipment are used.

Applications of Etched Stainless Steel

Examples where etched stainless is used include industrial nameplates, scientific equipment labeling, culinary knives, and fine jewelry. Students may design restaurant menus, laboratory reagent bottles, or school club logos engraved on stainless steel tags.

Etched steel resists corrosion while adding permanent identification or decorative markings with sharp detail. Its durability makes etched stainless steel suitable for long-term outdoor applications.

Tools and Equipment for Metal Etching

Laser Engraver - A laser engraving machine is necessary for precise laser etching. It features controls to set speed, power and optics to direct the laser beam. Always wear proper eye protection when operating.

Fume Extractor - When etching chemicals produce hazardous fumes, a fume extractor hood and proper ventilation are required. The fan removes fumes outdoors.

Etching Chemicals - Solutions like ferric chloride or sodium hydroxide dissolve targeted metal areas. Always use in a well-ventilated areas and avoid skin and eye contact by wearing protective gloves, apron, and goggles or face shield.

Surface Protectant - For chemical etching, apply a mask like wax, tape or lacquer where etching is not wanted. These protect areas from being etched accidentally.

Abrasives - Materials like wire brushes, emery paper or glass bead provide mechanical finishes. Wear eye protection and, for powders, a respirator mask to avoid breathing airborne particles.

Tips and Tricks for Successful Metal Etching

Preparation

Remove oils from metal surfaces using solvents so etchant adheres evenly. Lightly sanding improves adhesion.

Avoid thick paints or coatings that etchant cannot penetrate. Thin clear coats work best.

Accuracy

When using lasers, test power and speed settings on scrap material first. Go slowly for delicate areas.

With chemicals, agitate periodically to prevent uneven etching from chemical depletion areas.

Masking

Apply protective tape, paint or wax carefully to areas not to be etched, ensuring full coverage. Even small mistakes allow etching underneath.

For small holes or internal angles, use electric tape with sharp point to prevent leaks.

Fixing Mistakes

Minor mistakes can be covered with paint. For deeper issues, rework may be needed by re-etching or sanding affected region.

Thoroughly cleaning off etchant immediately after finishing prevents unwanted extra etching.

Conclusion

Exploring techniques like laser, chemical, and mechanical etching reveals how they permanently transform metal surfaces. Laser etching offers precise control for fine details and logos, especially on materials like aluminum and stainless steel.

This guide covers the tools, materials, and best practices to help beginners start their first metal etching projects.

Trust Unionfab with Your Metal Projects

We handle everything—from manufacturing to the finishing touches.

Unionfab provides a wide range of finishing options for all of your prototyping and production needs. Resquest a free and instant quote now!

To learn more about manufacturing processes, contact a Unionfab representative. We provide 24/7 assistance.