How to Engrave Metal: A Comprehensive Guide

Laser engrave metal or try traditional methods—this guide provides insights on how to get started, the best tools, and expert tips.

Introduction to Metal Engraving

Engraving metal allows for permanent markings on items like awards, nameplates, technical equipment, and jewelry. The engraving cuts into the material rather than just adding a surface design, making the text or image very durable and long-lasting.

There are mainly two types of engraving methods: manual and power-assisted.

Manual engraving is done by hand using specialized engraving tools to carefully cut lines into the metal.

Power-assisted engraving uses rotary tools or lasers that are computer-controlled. This allows for more precise and detailed work but requires specialized equipment.

In this guide, we will explain some commonly used manual and power-assisted engraving techniques.

Understanding Metal Engraving

What is Metal Engraving?

Metal engraving is a process that involves cutting intricate designs or text into a hard surface like metal. By removing thin layers of material, engraving leaves permanent impressions or markings in the metal.

Common Metals for Engraving

Some common metals engraved include:

Aluminum: A softer metal easy to engrave. Often used for nameplates and awards.

Brass: A stronger metal with a warm tone. Frequently engraved for plaques and memorials.

Steel: A strong, durable metal ideal for technical equipment. Commonly used for instrument panels.

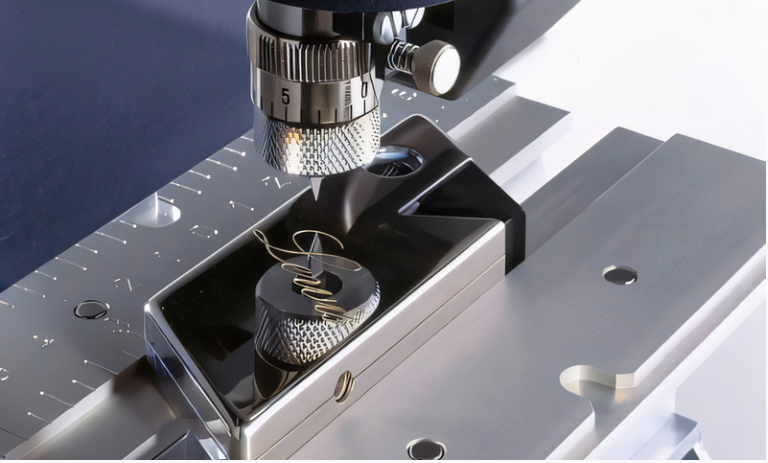

Laser Engraving vs. Traditional Methods

Source: The Goldsmiths' Center

There are two main types of engraving:

Laser engraving uses a high-power laser beam to precisely vaporize metal surfaces. It offers fast, complex designs but requires specialized equipment.

Traditional methods manually cut into metal using sharp engraving tools. This allows for fine detail work but takes more time. Rotary tools provide power-assisted traditional engraving.

How to Engrave Metal: Step-by-Step Guide

Step 1. Preparing the Metal Surface

Use sandpaper to remove any dirt or oxide layer from the metal's surface

For deep engraving, polish the surface with a fine-grit sandpaper

A smooth, clean surface ensures highest etching quality

Step 2. Choosing the Right Engraving Method

Hand engraving allows control but takes time; use for small items

Rotary tools speed up straight lines but manual for curves

Lasers efficiently cut complex designs but require equipment/training

Step 3. Selecting the Right Tools

For hand engraving, use burins, gravers or V-shaped rotary tools

For power tools, choose a Dremel or flex shaft system with cutters

For lasers, research CO2 or fiber options with appropriate power level

Step 4. Engraving Process

Hand engraving involves cutting lines using steady pressure and rotation

With power tools or lasers, use safety glasses and follow guides for speed, power, etc.

After etching, clean away debris to reveal the high-contrast engraving

With careful preparation and using the proper technique for the material, you'll be able to produce high-quality engraved designs on metal surfaces.

Tips and Best Practices for Metal Engraving

Achieving Precision and Consistency

Use alignment guides or stencils for straight lines

Go slowly and steadily to maintain even depth and width

For depth, apply light pressure at first and increase gradually

Avoiding Common Mistakes

Don't press too hard or cut will be uneven

Go with the grain to reduce snags or ragged edges

Clean frequently to avoid scratching with debris

Maintaining Your Engraving Tools

Hone tools regularly with a sharpening stone to keep edges sharp

Polish burins and gravers with very fine grit paper

Store properly oiled to prevent rusting or corrosion

Following some basic techniques can help you produce top-quality engravings. Taking your time, using guides, and properly caring for tools are keys to success.

Laser Engraving Metal: An Inside Look

How Laser Engraving Works

Laser engraving is a precise method that uses a high-powered laser beam to remove material from the surface of an object, creating a permanent mark or design. Here’s how it works:

Laser Source: A laser (typically CO2 or fiber) generates a focused beam of light.

Beam Focus: The laser beam is directed through mirrors and lenses to focus on a small area of the material’s surface.

Material Removal: As the laser hits the surface, it heats and vaporizes the material, carving away tiny layers to create the desired design or text. The depth of engraving can be controlled by adjusting the laser's intensity and duration.

Movement and Control: The laser is guided by a computer-controlled system, which follows a pre-designed pattern, ensuring precision in the engraving process.

End Result: The engraved area contrasts with the unmarked surface, producing a sharp, detailed image or text.

Benefits of Laser Engraving

Fast and Efficient

Laser engraving is a quick process, making it suitable for large-scale production without compromising on quality. The speed and automation also reduce labor costs.

High Precision and Detail

Laser engraving can create incredibly fine details, making it ideal for intricate designs, logos, and text. It ensures consistent, high-quality results, even for complex patterns.

Versatility on Different Materials

Laser engraving works on a wide variety of materials, including metals, wood, plastic, glass, leather, and even fabric. This versatility allows it to be used across industries like manufacturing, jewelry, and signage.

Non-Contact Process

The laser beam doesn’t physically touch the material, reducing the risk of damage or deformation. This is especially important for delicate or heat-sensitive materials.

Environmentally Friendly

Unlike chemical etching or traditional engraving methods, laser engraving doesn’t require harmful chemicals or produce significant waste, making it a more eco-friendly option.

Best Metals for Laser Engraving

Aluminum is easy to engrave and commonly used for its applications

Brass and bronze are more challenging but produce quality results

Stainless steel requires high-powered lasers due to its density

Choosing an Engraving Laser

Material Type

CO2 Laser: Best for non-metal materials like wood, acrylic, glass, leather, and plastics. It’s ideal for engraving organic and non-metallic surfaces.

Fiber Laser: Perfect for engraving metals like stainless steel, aluminum, and brass. It also works well on some plastics and is commonly used in industrial applications.

Diode Laser: Suitable for light engraving tasks on softer materials like wood and plastics. It's typically used for hobbyists or small projects.

Laser Power

Lower Power (20W-40W): Good for light engraving on softer materials like plastics, wood, and glass. Best for fine, shallow engravings.

Higher Power (50W-100W or more): Ideal for deeper engravings, cutting, or engraving tougher materials like metals or stone. Higher power allows for faster processing and greater flexibility.

Conclusion

Metal engraving is a precision process that lends permanent artistic and personalized touches to almost everything from awards to technical equipment.

Whether using manual techniques or advanced laser systems, achieving high-quality engraving takes practice with the proper preparation and tools.

Achieve Striking Custom Designs with Unionfab

Looking to customize parts with logos or designs? Unionfab’s laser masking service is the perfect solution.

Looking to elevate your product with personalized logos or custom designs? Unionfab's precision laser masking service transforms your vision into reality.

Get an instant quote in a minute! Or contact our expert team today to unlock seamless product identification and unique customization. Our dedicated support is available 24/7.

FAQs

How Do I Engrave Metal?

There are a few main methods: hand/manual engraving using specialist tools, rotary power tools like Dremels, and laser engraving machines. Proper preparation, tool selection and techniques are required based on the material and desired results.

What Metals Can Be Engraved?

Common choices are aluminum, brass, bronze and steel. Softer metals like aluminum are easier to engrave by hand. Harder metals require power tools or lasers. Stainless steel can only be engraved with high-powered lasers.

Why Isn't My Engraving Deep/Dark Enough?

Going too fast or applying too little pressure are common causes. With hand engraving, try slowing down strokes and increasing pressure gradually. For power tools, reduce speed and check the cutting bit is sharp.

How Do I Avoid Scratches in Metal Engraving?

Always work in a clean, well-lit area and periodically wipe away debris from the metal surface and engraving tools. Use pencil/chalk to mark guidelines rather than dragging tools.

What Are Tips for Metal Engraving Beginners?

Practice on scrap materials first. Go slowly, maintaining even depth and pressure. Hone tools regularly. Consider hiring an engraving specialist for complex projects until skills are developed. Proper technique improves with experience.