Can You Powder Coat Stainless Steel: Detailed Process

Can you powder coat stainless steel? Read this article to learn about the step-by-step process involved, and explore various applications.

Introduction

Powder coating stainless steel involves applying a dry powder finish to the steel, creating a durable and attractive layer.

Unlike traditional liquid paints, powder coating offers several advantages, making it a compelling option for various applications.

Source: inbound.cammmetals.com

Understanding: Powder Coating Stainless Steel

Importance of Powder Coating

While stainless steel boasts impressive resilience, there are situations where powder coating can elevate its functionality and aesthetics.

Enhanced Corrosion Resistance

Powder coating can act as an additional barrier against harsh chemicals or environmental elements, potentially extending the lifespan of the stainless steel in specific conditions.

Color and Design Freedom

Unlike the traditional stainless steel look, powder coating unlocks a vast spectrum of colors and finishes, allowing for creative design expression and brand alignment.

Improved Durability

Powder coating creates a tough, impact-resistant layer that can protect the underlying stainless steel from scratches, abrasions, and even UV rays in outdoor applications.

Increased Functionality

Certain powder coatings can offer additional properties like electrical insulation, improved grip, or anti-microbial properties, depending on the chosen material.

Overview of Stainless Steel Properties

Chromium Rich Surface

When exposed to oxygen, a thin, invisible layer of chromium oxide forms on the surface, a passive layer that shields the steel from corrosion.

Alloy Composition

The specific properties of stainless steel depend on the type of alloy used. Common variations include 304 (general-purpose) and 316 (marine-grade) stainless steel, each offering varying degrees of corrosion resistance.

Low Surface Energy

Due to its chromium oxide layer, stainless steel has a naturally low surface energy. This characteristic can sometimes make it challenging for traditional paints to adhere properly.

Benefits of Powder Coating Stainless Steel

Superior Adhesion: Powder coating uses a static charge to attract the powder particles to the stainless steel surface. This method ensures excellent adhesion compared to traditional liquid paints.

Environmentally Friendly: Powder coating is a solvent-free process, minimizing harmful VOC (volatile organic compound) emissions compared to traditional paints.

Durable and Long-Lasting: Powder coatings are known for their exceptional durability, resisting chipping, fading, and scratches better than many liquid paints.

Cost-Effective: While the initial setup costs might be higher, powder coating's durability and reduced waste can lead to lower long-term costs compared to traditional painting.

Versatility Across Applications: From architectural elements and appliances to automotive parts and medical equipment, powder-coated stainless steel finds applications in various industries due to its unique blend of aesthetics and functionality.

Powder Coating Process for Stainless Steel

Surface Preparation

Cleaning and Degreasing: Thorough cleaning removes dirt, grease, or oils that could hinder the powder's adhesion. This might involve detergents, solvents, or specialized cleaning solutions.

Sandblasting or Abrasive Blasting: This step creates a microscopic texture on the stainless steel surface, increasing the surface area and enhancing the mechanical bond between the powder coating and the metal.

Application of Powder Coating

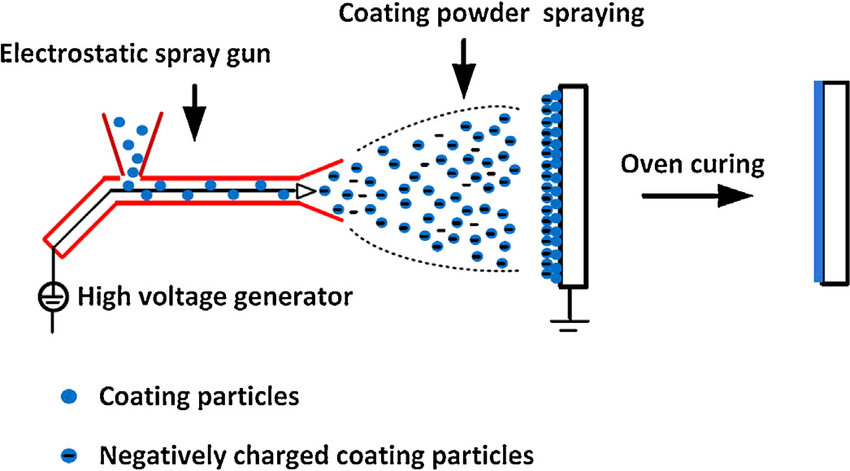

Electrostatic Application

Source: researchgate.net

This is the most common method. The powder particles are electrically charged, attracting them to the grounded stainless steel workpiece.

This ensures a uniform and complete coverage, even on complex shapes.

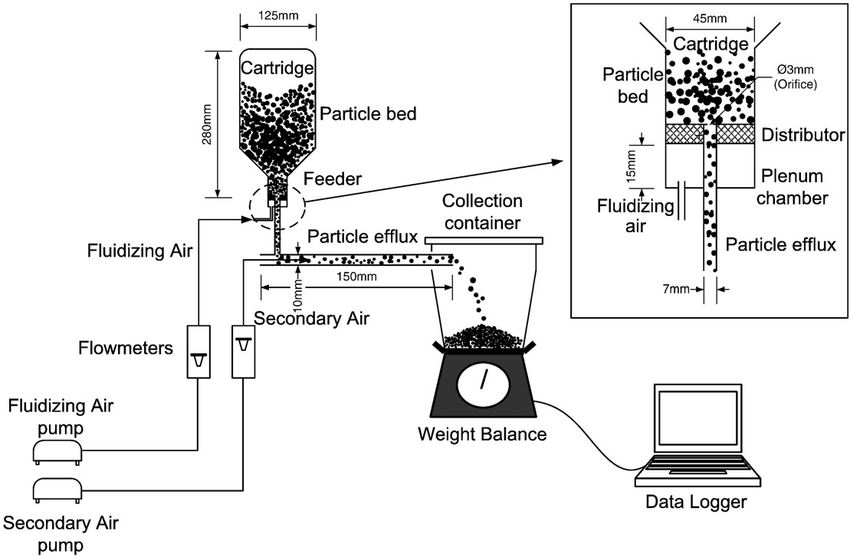

Fluidized Bed Application

Source: researchgate.net

This method is often used for smaller parts or those with intricate details.

Curing Process

Heat Curing

This is the most widely used curing method. The coated stainless steel piece is exposed to high temperatures (typically between 350°F and 450°F) for a controlled period.

This heat melts the powder particles, causing them to flow together and form a continuous, hard-wearing layer.

UV Curing

A less common but increasingly explored option is UV curing. Here, the powder coating contains photoinitiators that react to ultraviolet light.

Exposing the coated piece to UV radiation triggers a rapid curing process, offering advantages like lower energy consumption and potentially faster processing times.

Types of Powder Coatings for Stainless Steel

Thermoplastic Powders

These powders soften and melt upon heating during the curing process. As they cool, they solidify without undergoing a permanent chemical change.

Thermoplastic coatings offer good flexibility and chemical resistance, and come in a wide variety of colors. However, they may not be as heat resistant as thermoset options.

Thermoset Powders

Thermoset powders undergo a permanent chemical reaction when cured.

The heat triggers a cross-linking process that hardens the coating, resulting in a very durable and chemical-resistant finish. Thermoset coatings generally offer superior heat resistance compared to thermoplastics.

Common Coating Materials

Epoxy

A popular thermoset choice, known for its excellent chemical resistance, good adhesion, and wide range of colors.

Epoxy coatings are a good choice for parts that will be exposed to harsh chemicals or require superior electrical insulation.

Polyester

Another versatile thermoset option, offering good durability, weather ability, and a broad color spectrum.

Polyester coatings are a cost-effective choice for various indoor and outdoor applications on stainless steel.

Polyurethane

A versatile thermoplastic option, known for its flexibility, impact resistance, and excellent aesthetics.

Polyurethane coatings are a good choice for parts requiring a high-gloss finish or those that may experience some bending or flexing.

Maintenance of Powder-Coated Stainless Steel

Cleaning Techniques

General Cleaning

For everyday cleaning, use a mild soap solution with lukewarm water and a soft microfiber cloth.

Avoid abrasive cleaners, scouring pads, or harsh chemicals, as these can scratch the powder coating.

Tackling Tough Stains

For stubborn stains, use a gentle degreaser or a solution of white vinegar and water (50/50 mix).

Apply the cleaning solution with a microfiber cloth, then rinse thoroughly with clean water and dry completely with another soft cloth.

Avoiding Damage

Heat Resistance

While powder coatings are generally heat resistant, avoid exposing them to extreme or continuous high temperatures exceeding their specified limits. This can cause the coating to discolor or warp.

Impact and Scratching

While the powder coating offers good scratch resistance, avoid using sharp objects or abrasive materials on the surface, as they can damage the coating.

Chemical Exposure

Certain chemicals, such as abrasive cleaners, strong solvents, and bleach can damage the powder coating.

Identify the type of powder coating used and consult with the manufacturer for a list of compatible and incompatible chemicals.

Touch-Up Procedures

Small Imperfections: For small scratches, a wax stick designed for clear coats can sometimes help buff out the blemish. Apply a small amount with a soft cloth and buff gently.

Larger Scratches: For more prominent scratches that have penetrated the coating, consult with a professional about potential touch-up options. Depending on the severity and the type of powder coating used, they might recommend spot repairs or refinishing the entire piece.

Long-Term Maintenance Tips

Regular Cleaning: Maintain a consistent cleaning routine to prevent dirt and grime buildup that can dull the finish.

Periodic Inspections: Periodically inspect the surface for any signs of damage or wear. Addressing minor issues promptly can prevent them from becoming bigger problems.

Environmental considerations: For outdoor applications, consider the specific environmental conditions. Harsh sunlight or extreme weather might necessitate more frequent cleaning or choosing a UV-resistant powder coating material.

Applications of Powder-Coated Stainless Steel

Industrial Equipment

Machinery and Parts

Powder-coated stainless steel components in machinery benefit from enhanced corrosion resistance, improved scratch and wear resistance, and a wider range of colors for easier identification or coding.

Chemical Processing Equipment

The ability of certain powder coatings to withstand harsh chemicals makes this material suitable for tanks, pipes, and other equipment in chemical processing plants.

For example, Pipes handling corrosive liquids can be powder coated with a specific fluoropolymer resin to withstand harsh chemicals and ensure long-lasting performance.

Food Processing Equipment

Powder coatings can offer a hygienic, easy-to-clean surface for equipment in food processing facilities, while still maintaining the inherent cleanability of stainless steel.

Automotive Parts

Wheels and Rims

Powder coating offers a durable, chip-resistant finish for wheels, enhancing their appearance and protecting them from road debris and harsh weather conditions.

Trim and Decorative Elements

Car manufacturers can utilize powder coating to create a wider variety of color options for trim pieces, emblems, and other decorative elements on vehicles.

Undercarriage Components

Powder coating can provide additional corrosion protection for undercarriage components exposed to road salt, moisture, and debris.

Architectural Structures

Building Facades: Cladding panels, railings, and other exterior elements can be powder coated for a visually striking and weather-resistant finish.

Interior Design Elements: Elevator doors, wall panels, and other interior components can benefit from powder coating's aesthetics and ease of cleaning.

Signage and Architectural Accents: Powder coating allows for vibrant colors and unique finishes for signage, creating a lasting visual impact.

Consumer Goods

Appliances: From refrigerators and dishwashers to ovens and microwaves, powder coating enhances appliance aesthetics while offering improved scratch and fingerprint resistance.

Furniture: Outdoor furniture, kitchenware, and other household items can benefit from powder coating's durability and ability to withstand everyday wear and tear.

Sporting Goods: Bicycle frames, skis, and other sporting equipment can be powder coated for a sleek look and improved weather resistance.

Marine Applications

Boat Parts: Handrails, hatches, and other boat components can be powder coated for a long-lasting, corrosion-resistant finish that withstands saltwater exposure.

Offshore Equipment: Oil rigs, platforms, and other offshore structures can utilize powder-coated stainless steel for its durability and resistance to harsh marine environments.

Marine Hardware: Anchors, cleats, and other hardware benefit from powder coating's protective properties, ensuring longevity in challenging saltwater conditions.

Conclusion

Powder-coated stainless steel offers a powerful combination of functionality, durability, and aesthetics.

From the vibrant casings of industrial robots to the sleek car trim, and from the weather-resistant cladding of marine structures to the hygienic surfaces of food processing equipment, powder-coated stainless steel finds its way into a vast array of applications.

Achieve the Best Production Quality with Unionfab

In today's competitive landscape, consistent quality is the cornerstone of manufacturing success. Unionfab understands this and is dedicated to being your partner in achieving flawlessly manufactured parts.

Contact us now! Let's unleash the value of your products!