Beveled Edges: A Detailed Guide to Bevel vs. Chamfer Edge

Gain a clear understanding of beveled and chamfer edges with this insightful guide.

Introduction

A beveled edge, where the sharp 90-degree angle is cut at a sloping angle, is a popular finish used in various industries, including furniture, architecture, and metalwork.

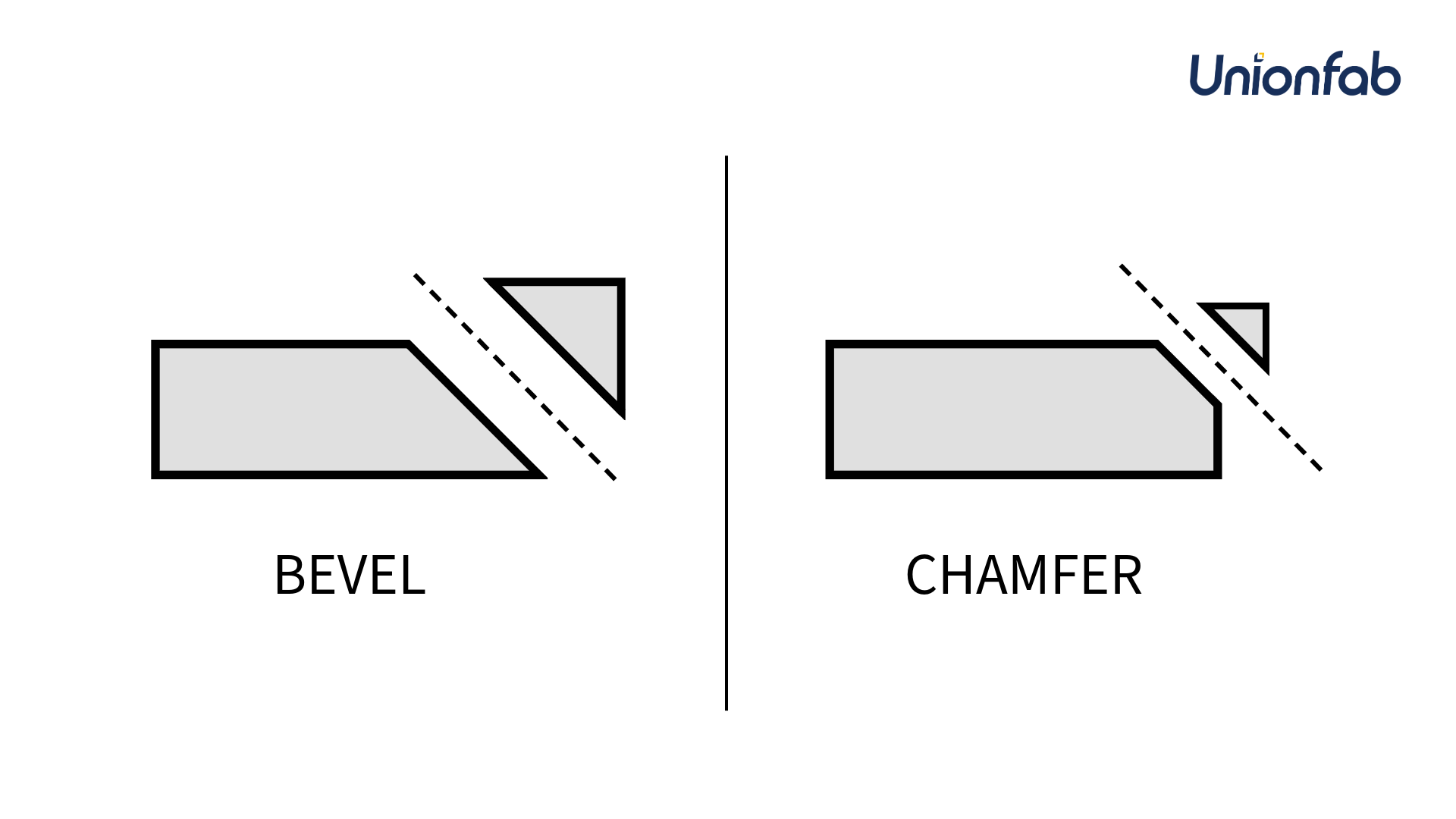

Beveled and chamfered edges are two common edge finishing techniques. However, it can sometimes be unclear what project applications are best served by each style.

What is a Beveled Edge?

A beveled edge is a slanted surface that connects two surfaces at an angle, usually between 25 and 45 degrees, rather than a sharp 90-degree angle.

This angled edge creates a smooth transition, giving objects a softer look and feel.

What is a Chamfer Edge?

Imagine the corner of a solid block where the sharp corner has been flattened at a 45-degree angle. This flat surface is called a chamfer.

Chamfered edges are commonly used in mechanical parts, electronic devices, and architectural designs. They provide benefits like improved safety, better stress distribution, and easier machining compared to sharp edges.

Bevel vs. Chamfer: Key Differences

This table offers a comprehensive comparison between bevel and chamfer edges:

Aspect | Beveling | Chamfering |

|---|---|---|

Geometry | Angled, variable slope | Flat, fixed 45-degree angle |

Functionality | Aesthetics, safety, depth | Assembly ease, stress distribution |

Tooling | Complex, adjustable angles | Simple, standard tools |

Process Complexity | More intricate, multi-step | Straightforward, single-step |

Material Use | Metal, wood, plastics, glass, stone and tile | Metal, wood, plastics |

Common Applications | Furniture, glasswork, architecture | Mechanical parts, electronics, tools |

Flexibility | High, customizable angles | Low, standardized angle |

Precision Required | High, especially in decorative work | Moderate, functional precision |

Comparing Table: Bevel vs. Chamfer

There are important distinctions between beveled and chamfered edges in their geometry, functionality, and manufacturing process.

Geometry

A bevel forms a sloping surface at an angle, whereas a chamfer is a flat, straight edge where two surfaces meet at an angle.

While the angle of a bevel can vary, offering flexibility in design, a chamfered edge is typically cut at a 45-degree angle.

Functionality

Beveled edges are often used to aesthetically soften sharp corners for a smoother, more visually appealing design. They also improve safety by reducing the risk of cuts from sharp edges.

Chamfered edges, on the other hand, primarily serve functional and engineering needs. They help with the assembly of parts by eliminating sharp right angles that could interfere with fitting. Chamfers also reduce wear on edges and help distribute stress more evenly, which is especially important in mechanical parts that need to withstand forces.

Manufacturing Process

Complex Tooling for Beveling: Beveling can involve cutting edges at a range of angles, not just the standard 45 degrees. This flexibility in angle requires adjustable or specialized tools, such as multi-axis CNC machines, beveling machines, or grinders that can accommodate different angles and depths.

Since bevels can be created at different angles, the process might involve more precise adjustments and setups, depending on the desired outcome.

Simpler Process for Chamfering: Chamfering usually involves creating a 45-degree angle, which is a more standardized process. This can be done using more common tools like chamfer mills, routers, or even manual tools, making it easier and quicker to produce.

The uniformity of the 45-degree angle in chamfering simplifies the process, reducing the need for complex adjustments or specialized equipment.

Material Types and Applications

Metals: Metals like steel, aluminum, and brass are often machined with chamfered edges, especially in mechanical and industrial applications. Beveling metal, on the other hand, is more common in decorative or structural components. However, beveling metal usually requires more complex tooling and precise control, especially for harder metals.

Wood: Wood can be easily shaped with either beveled or chamfered edges. Beveled edges are popular in woodworking for their aesthetic appeal, often used in furniture, cabinetry, and trim work to create smooth, elegant transitions. Chamfered edges in wood are typically used to create a clean, sharp finish, often in more functional pieces where the edge needs to be durable.

Plastics: Plastics, like acrylic, polycarbonate, or PVC, can be chamfered or beveled depending on the application. Chamfering is common in plastic components used in mechanical or electronic assemblies. Beveling plastic is often done for aesthetic reasons, particularly in display cases, signage, or consumer products.

Glass: Glass is typically beveled rather than chamfered, as the sloping edge of a bevel not only adds a decorative element but also helps to reduce the risk of chipping along sharp edges. Beveled edges in glass are commonly seen in mirrors, tabletops, and architectural glass panels.

Stone and Tile: Stone and tile materials, like granite, marble, and ceramic, often feature beveled edges in countertops, flooring, and decorative elements. The bevel softens the transition between surfaces and adds an elegant finish. Chamfering is also used, particularly in flooring or tiling projects.

In conclusion, Beveling allows for more varied angles and shapes, but requires specialized tools to produce sloped edges. Chamfering produces a flat, linear edge and is generally quicker and easier to do using common tools like files or mills.

Bevel vs. Chamfer: Choosing the Right Edge

When selecting an edge finish, carefully evaluate the project requirements. Two primary factors to consider are:

Engineering/Functionality Needs - Chamfer Edges

For parts with significant engineering or functional goals, chamfer edges optimize part performance in mechanical, structural and operational applications as they:

Ease assembly of interlocking components

Distribute stress more evenly over surfaces

Increase durability by reducing wear on corners

Aesthetic/Design Needs - Bevel Edges

In projects with strong aesthetic or design objectives, bevel edges allow more control over shaping edges to creative contouring and visual effects as they:

Provide a more refined, visually appealing profile

Enhance the overall look and styling of a product

Soften harsh edges in furniture, architectural details, etc.

Conclusion

In summary, a beveled edge offers a sloped, angled profile that enhances aesthetics, while a chamfered edge creates a flat, straight cut that improves functionality, such as stress resistance and ease of assembly.

Let Unionfab Handle Your CNC Project

With over 20 years of experience, Our ISO-certified CNC services can handle demanding specifications. Tight tolerances and flawless finishes are our specialty.

Get a quote today or contact us to discuss your project requirements!