Vapor Smoothing: Elevating 3D Printing

This article introduces the definition, mechanism and applications of vapor smoothing, with a specific focus on vapor smoothing PLA and ABS.

Introduction

Vapor smoothing offers a streamlined solution to refine the surface finish and structural integrity of printed objects.

This article provides a brief overview of vapor smoothing, highlighting its tailored applications with PLA and ABS materials.

What is Vapor Smoothing

Definition

Vapor smoothing is a post-processing method employed in additive manufacturing to enhance the surface finish and overall quality of printed objects.

This process involves subjecting printed objects to controlled exposure to vaporized solvents or chemicals within a controlled environment, inducing a chemical reaction that softens and reshapes the outer layer of the print.

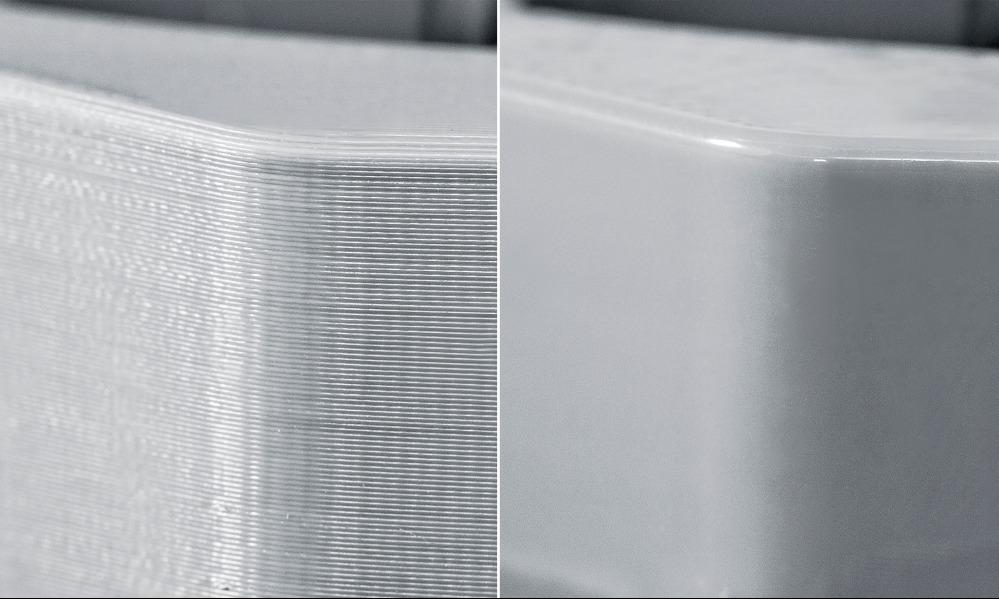

It results in a smoother surface finish, free from visible layer lines and imperfections.

Common Materials

PLA (Polylactic Acid): PLA is biodegradable and has a low melting point, ideal for eco-friendly applications. Vapor smoothing PLA improves surface smoothness and aesthetics.

ABS (Acrylonitrile Butadiene Styrene): ABS is durable with high impact resistance, commonly used in automotive and electronics. Vapor smoothing ABS enhances surface quality and mechanical properties for optimal results in manufacturing.

PLA and ABS respond well to vapor smoothing due to their composition, making them ideal for the process.

Importance of Vapor Smoothing in 3D Printing

Enhancing Quality: Vapor smoothing improves the quality of 3D-printed objects by refining surface texture, strengthening structure, and ensuring precise dimensions.

Mitigating Imperfections: It helps in reducing common imperfections like visible layer lines and rough surfaces associated with additive manufacturing.

Elevating Aesthetic Appeal: By smoothing out surfaces, vapor smoothing enhances the aesthetic appeal of printed objects.

Improving Structural Integrity: Vapor smoothing enhances the structural integrity of 3D-printed objects by strengthening bonds between layers, reducing the risk of breakage.

Expanding Applicability: Vapor smoothing broadens the range of industries and applications where 3D printing can be effectively utilized by ensuring high-quality finishes and improved functional properties.

How Vapor Smoothing Works

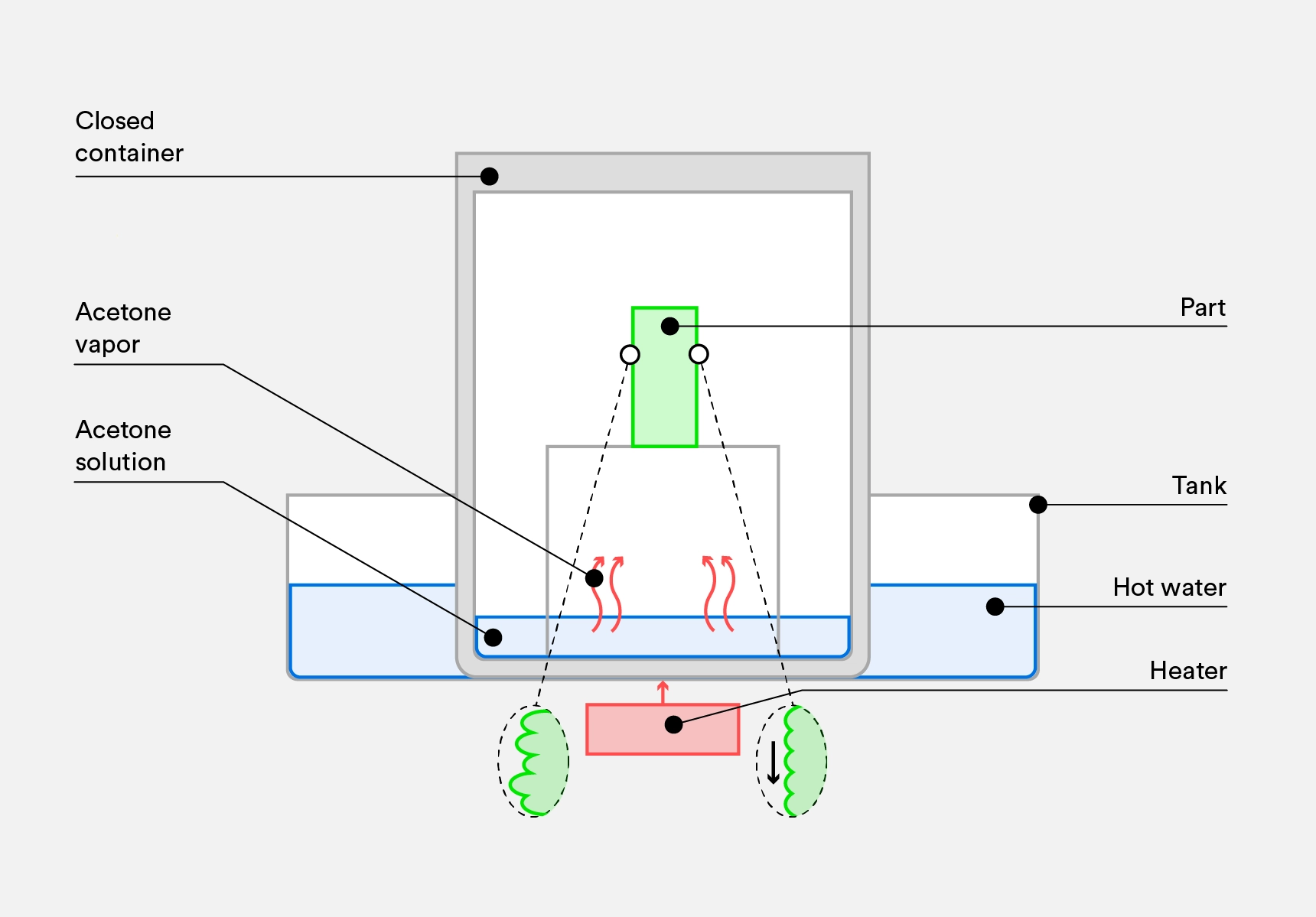

Vapor Smoothing Machines

Specialized vapor smoothing machines facilitate the controlled exposure of printed objects to solvent vapors within a controlled environment:

Controlled Environment: Provides regulated setting for exposing prints to solvent vapors.

Temperature and Humidity Control: Precise mechanisms ensure ideal conditions for smoothing.

Safety Features: Includes safeguards like ventilation systems to prevent accidents.

Variety of Sizes: Available in different dimensions to accommodate various print sizes.

Automated Operation: Some offer automated functions for consistent results.

The Process

Vapor smoothing process involves several steps:

Step 1. Preparation

Before vapor smoothing, the printed objects undergo a thorough cleaning process to ensure the removal of any dirt, dust, or residue that could interfere with the process.

Step 2. Placement

Once cleaned, the objects are carefully positioned either by suspending them from racks or placing them on specialized trays within the chamber, ensuring even exposure to the solvent vapors.

Step 3. Exposure

Within the controlled environment of the vapor smoothing chamber, solvent vapors are introduced gradually, surrounding and penetrating the surface of the printed objects to initiate the smoothing process.

Source: ctfassets.net

Step 4. Reaction

As the solvent vapor comes into contact with the surface of the print, it triggers a chemical reaction that softens and reshapes the outer layer, effectively smoothing out imperfections and surface irregularities.

Source: cdn.thefabricator.com

Step 5. Drying

After achieving the desired level of smoothness, the objects are removed from the chamber and left to dry thoroughly, allowing the solvent to evaporate and the softened surface to solidify, resulting in a smooth and polished finish.

Vapor Smoothing PLA

Steps of Vapor Smoothing PLA

Preheat: The PLA print is preheated to ensure uniform exposure to vapor.

Vapor Exposure: The print is introduced into the vapor chamber and exposed to solvent vapors.

Drying: After achieving the desired smoothness, the print is allowed to dry thoroughly.

Applications of Vapor Smoothed PLA

Product Prototyping: In product development, vapor smoothing PLA enhances the appearance and functionality of prototypes, providing a polished finish ideal for presentations and testing.

Consumer Goods: PLA prints treated with vapor smoothing find applications in the production of consumer goods such as custom-designed phone cases, jewelry, and household items, where a smooth and aesthetically pleasing finish is desired.

Medical Devices: Vapor smoothed PLA components are utilized in the manufacturing of medical devices and equipment, ensuring biocompatibility, smooth surfaces for hygiene, and precision in medical prototypes.

Educational Models: In educational settings, vapor smoothed PLA prints are valuable for creating detailed and visually appealing models used in classrooms and laboratories for teaching purposes.

Artistic Sculptures: Artists and sculptors utilize vapor smoothing PLA to produce intricate and flawless sculptures, benefiting from its smooth finish and ease of post-processing for artistic endeavors.

Vapor Smoothing ABS

Steps of Vapor Smoothing ABS

Preparation: The ABS print is prepared by cleaning and inspecting for imperfections.

Vapor Treatment: The print is exposed to solvent vapors within the controlled environment.

Post-Treatment: After vapor exposure, the print is left to dry completely.

Applications of Vapor Smoothed ABS

Prototyping: Crucial for precise and visually appealing prototypes, aiding design validation.

Consumer Goods: Enhances aesthetic appeal in items like phone cases and decor.

Medical Applications: Vital for hygienic medical equipment prototypes, ensuring easier cleaning.

Educational Models: Used in educational settings to create detailed teaching aids for subjects like biology and engineering.

Artistic Expression: Enables artists to craft intricate sculptures with a professional finish.

Functional Parts: Reliable for durable components in industries like automotive and aerospace due to enhanced finish and structural integrity.

Benefits of Vapor Smoothing

Enhanced Aesthetics

Vapor smoothing creates a smooth, flawless surface free of visible layer lines, enhancing the overall appearance and aesthetic appeal of printed objects.

This process is particularly beneficial for detailed designs and intricate models, providing a professional finish suitable for various applications.

Improved Strength and Durability

Vapor smoothing strengthens printed objects, improving their durability and reducing the risk of breakage and wear, which is crucial for functional prototypes and mechanical components, ensuring reliable performance in demanding conditions.

Minimization of Printing Defects

Vapor smoothing minimizes defects such as warping and layer separation, improving print quality and meeting precise dimensional specifications. This consistency is ideal for applications requiring precision and reliability.

Time and Cost Efficiency

Compared to manual finishing methods, vapor smoothing offers a faster and more cost-effective solution for achieving high-quality surface finishes.

The automated process reduces labor requirements and production time, leading to increased efficiency and reduced overall costs per unit.

Applications

Automotive and Transportation

Enhanced aesthetics and durability: Vapor smoothing is utilized to improve the appearance and longevity of automotive components such as exterior body panels, alloy wheels, and interior trim pieces.

Corrosion resistance: The process helps mitigate corrosion on vehicle parts like exhaust systems, engine components, and suspension elements, extending their service life in harsh environmental conditions.

Aerospace and Aviation

Surface finish for aerodynamics: Vapor smoothing is employed to refine the surfaces of aircraft wings, fuselage components, and engine nacelles, reducing drag and enhancing fuel efficiency.

Fatigue resistance: The process strengthens critical aerospace components like turbine blades, landing gear parts, and structural elements, ensuring they withstand high stress and fatigue loads during flight.

Medical Devices and Implants

Biocompatibility enhancement: Vapor smoothing is utilized to improve the biocompatibility of medical devices and implants such as surgical instruments, prosthetic limbs, and orthopedic implants, reducing the risk of adverse reactions in patients.

Surface hygiene: The process creates smooth surfaces on medical equipment components, facilitating easier cleaning and sterilization, crucial for maintaining hygiene standards in healthcare settings.

Conclusion

Vapor smoothing is a crucial technique in 3D printing, improving both aesthetics and structural integrity. Its versatility across materials like PLA and ABS is invaluable across industries from automotive to consumer goods.

Serving as a cost-effective solution to common print imperfections, vapor smoothing drives innovation and precision in additive manufacturing, ensuring higher standards of excellence in 3D-printed products.

Achieve Flawless Finishing at Unionfab

At Unionfab, we focus on providing advanced 3D Printing finishing solutions, including vapor smoothing services, to ensure that your projects receive perfect surface finishing effects.

In addition, we also offer a variety of 3D Printing services such as Stereolithography (SLA),Selective Laser Melting (SLM), and Selective Laser Sintering (SLS).

Contact Us for more finishing and manufacturing options!