Types of CNC Machines: Exploring the Diversity

Get ready to explore the world of different types of CNC machines in today's manufacturing landscape.

Introduction

In this article, we'll explore the different types of CNC machines and how they're used to achieve high precision, increased productivity, enhanced design flexibility, reduced waste, and improved safety in modern manufacturing.

Basic Types of CNC Machines

The world of CNC machining boasts a diversity of machines, each with its own specialty.

CNC Milling Machines

These machines are adept at creating intricate 3D shapes and features. They use a rotating cutting tool to remove material from a workpiece, and can move along multiple axes (X, Y, and Z) to achieve complex geometries.

CNC Lathes

Lathes are often used to create cylindrical and spherical parts. A workpiece is secured and rotated on a spindle, while a cutting tool is positioned along the Z-axis to remove material and achieve the desired shape.

CNC Drilling Machines

These machines specialize in drilling holes of various sizes and depths into workpieces. They can be either single-spindle or multi-spindle, and offer precise control over hole location, size, and depth.

Comparision: Milling,Lathe & Drilling

Feature | Milling Machine | Lathe | Drilling Machine |

|---|---|---|---|

Process | Subtractive (Rotates tool) | Subtractive (Rotates workpiece) | Subtractive (Drills holes) |

Material | Metals, plastics, wood | Metals | Various (depends on bit) |

Strengths | Intricate 3D shapes | Cylindrical & spherical parts | Precise holes |

Applications | Parts with slots, pockets, engravings | Shafts, gears, bearings | Electronics, circuit boards, furniture |

Speed | Varies (complex shapes) | High (simple parts) | Moderate (multiple holes) |

Cost | High (multi-axis) | Mid-range | Low (simpler design) |

Advanced Types of CNC Machines

In addition to basic workhorses we have known,there are varieties of advanced CNC machines, each with its own advantages and applications.

CNC Plasma Cutters

CNC plasma cutters utilize a high-temperature plasma torch to melt and blow away material from the workpiece. This allows for fast, high-volume cutting of conductive materials like steel and aluminum.

Plasma cutters are perfect for applications like sheet metal fabrication, construction, and signage.

CNC Laser Cutting Machines

CNC laser cutters focus concentrated beams of light to vaporize material with high precision. This method offers unmatched cutting accuracy and detail, allowing for intricate cuts on a wide range of materials, including metals, plastics, wood, and even fabrics.

Laser cutters are ideal for applications in the electronics, medical device, and delicate metalwork industries.

Comparison: Plasma Cutter & Laser Cutter

Feature | Plasma Cutter | Laser Cutter |

|---|---|---|

Action | Cuts (Subtractive) | Cuts (Subtractive) |

Material | Conductive Metals | Wide Range |

Strength | Fast, High-Volume | Precision & Intricate Cuts |

Applications | Sheet Metal, Signage | Electronics, Delicate Metalwork |

Speed | High (Sheet Metal) | Moderate |

Cost | Lower | Mid-Range to High |

Specialized Types of CNC Machines

CNC Router Machines

CNC routers are essentially computer-controlled versions of traditional woodworking routers. They utilize a high-speed rotating cutting tool to carve shapes and remove material from a broad spectrum of materials.

Unlike milling machines primarily focused on metals, CNC routers excel at working with softer materials like wood, plastics, composites, and even aluminum. These machines are ideal for applications like cabinetry, signage, mold making, and 3D carving.

CNC EDM Machines

These machines utilize precisely controlled electrical sparks to erode material from the workpiece. This allows for highly precise machining of very hard metals, exotic alloys, and even fragile materials that would be difficult or impossible to machine with conventional methods.

CNC EDM machines are essential for creating complex shapes and features in tools, dies, molds, and aerospace components.

CNC Wire EDM Machine

These machines utilize a continuously spooled wire electrode and a series of electrical discharges to precisely cut intricate shapes and profiles in a variety of conductive materials.

The thin wire allows for machining of very tight corners and small features, making it ideal for applications like dies, punches, and intricate parts for the aerospace and electronics industries.

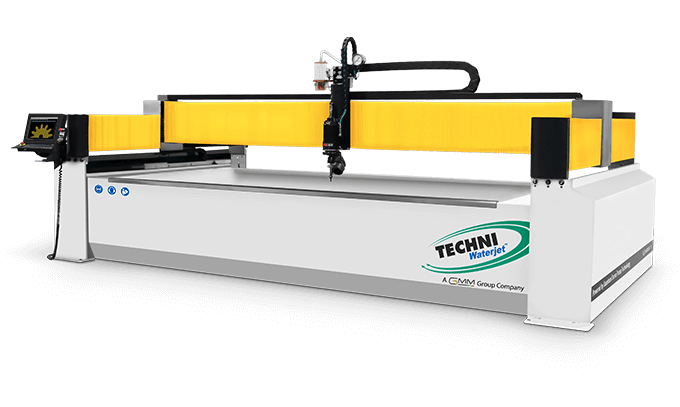

CNC Waterjet Cutting Machines

CNC waterjet cutting machines utilize a high-pressure stream of water, often mixed with abrasive particles, to cut through a wide range of materials. This method offers a clean, cool cutting process that doesn't generate heat-affected zones, making it ideal for materials sensitive to heat, such as composites and certain plastics.

CNC waterjet cutters are versatile tools used for applications in construction, aerospace, automotive, and gasket manufacturing.

Comparison: Router vs. EDM vs. Wire EDM vs.Waterjet

Feature | Router | EDM | Wire EDM | Waterjet |

|---|---|---|---|---|

Action | Cuts (Soft Materials) | Erodes (Hard Metals) | Erodes (Delicate Metals) | Cuts (Wide Range) |

Material | Wood, Plastics | Very Hard Metals | Hard Metals | Metals, Composites, Plastics |

Strength | Precise Details | Complex Shapes | Intricate Features | Clean, Cool Cuts |

Applications | Cabinetry, Signage | Tools, Dies, Molds | Aerospace, Electronics | Construction, Gaskets |

Heat Affected Zone? | No | No | No | No |

Speed | Moderate | Slow | Slow | Moderate |

Cost | Lower | High | High | Mid-Range |

Advantages of CNC Machines

Increased Productivity

Faster Speeds & Reduced Setups

Unlike manual machining with frequent tool changes and downtime, CNC machines operate 24/7 with quick program changes. This translates to significantly faster production times, ideal for high-volume runs.

Consistent Quality & Automation

CNC machines rely on computer-controlled movements, ensuring every part is a near-perfect replica of the digital design. This level of automation frees up skilled workers for other tasks and minimizes human error.

Precision and Accuracy

Repeatable Accuracy

CNC machines always guarantee near-perfect parts, thanks to their precise computer-controlled movements. This allows for tighter tolerances and more complex designs.

Complex Designs Made Easy

Multi-axis capabilities enable the creation of intricate 3D shapes and features,tackling intricate shapes impossible with manual machining.

Minimal Material Waste

Precise cutting minimizes material waste. CNC machines only remove the necessary material from the workpiece, saving on costs and minimizing environmental impact.

Versatility in Design

Material Master

CNC machines can handle a wide range of materials, from soft woods and plastics to hard metals and exotic alloys. This versatility allows for the creation of prototypes, functional parts, and even finished products from a single machine.

Rapid Prototyping Powerhouse

The ability to quickly create prototypes from digital designs is good for product development. Engineers and designers can iterate and refine designs rapidly, leading to faster time-to-market and improved product quality.

Customization Champion

Digital designs allow for easy part changes. This makes CNC machining ideal for low-volume production runs and personalized products, giving businesses the ability to cater to specific customer needs.

A Guide on Selecting CNC machines

Selecting the perfect CNC machine requires careful evaluation of several factors.

Project Requirements

Material compatibility: Not all CNC machines work with all materials. Identify the materials you'll be using and choose a machine specifically compatible with them.

Part complexity: Simple parts requiring basic cuts might be suited for a simpler machine.Intricate 3D shapes demand a machine with more axes and advanced capabilities.

Production volume: High-volume production might benefit from faster machines, while low-volume runs might prioritize flexibility.

Machine Capabilities

Machine type: Different machine types excel at different tasks. Milling machines handle complex 3D shapes, lathes create cylindrical parts, and routers work well with softer materials.Choose the machine type best suited for your project.

Number of axes (3, 4, or 5): The number of axes determines the machine's movement freedom. 3-axis machines move on X, Y, and Z planes, while 4 or 5-axis machines offer additional rotational capabilities for intricate designs.

Work area size and travel: Consider the size of your parts and the travel distance (movement range) of the machine's axes. Ensure the machine has enough space to accommodate your projects.

Budget and Costs

Machine cost: CNC machines can range significantly in price depending on capabilities and features. Determine your budget and prioritize features essential for your projects.

Installation and setup costs: Factor in the cost of installation, training, and any additional software needed to operate the machine.

Maintenance costs: Regular maintenance is crucial for optimal performance. Consider the ongoing costs of parts, service, and potential upgrades.

Additional Considerations

Ease of Use

Evaluate the machine's user interface and control system. Consider the skill level of operators and choose a machine that offers user-friendly operation. Training resources and technical support from the manufacturer can also be important factors.

Safety Features

CNC machines can be powerful tools. Ensure the machine has proper safety features like guards, emergency stops, and proper ventilation (especially for dust or fumes) to protect operators.

Warranty and Support

A solid warranty and reliable after-sales support are crucial for long-term peace of mind. Look for a manufacturer with a good reputation for customer service and readily available support should you encounter any issues.

Conlusion

CNC machining has become a cornerstone of modern manufacturing due to its unbeatable combination of speed, precision, and design flexibility.

This translates to faster production times, reduced waste, and the ability to create intricate designs that were once impossible.

Custom Online CNC Machining Services at Unionfab

Unionfab offers various of CNC machining services, including CNC Turning, CNC Milling,CNC Routing,Wire EDM and so on.Here is an extensive collection of over 50 CNC lathes and CNC turning centers to produce meticulously accurate round or cylindrical turned parts. Additonally,Unionfab support 3-axis, 4-axis, 5-axis milling, and right-angle milling.

All of these will help you streamline project workflow, access advanced manufacturing capabilities, and get high-quality parts produced efficiently and affordably!