PLA vs. ABS vs. PETG: A Comprehensive Comparison

PLA, ABS, and PETG are 3D printing filaments with unique properties and this article explores their strengths and helps you decide which is best for your project.

Introduction

When it comes to 3D printing, material selection can make or break your project—literally. Whether you're a product designer validating form and fit, an engineer prototyping functional parts, an educator printing classroom models, or a maker building creative pieces, the right filament ensures your print is successful, durable, and cost-effective.

Among the most widely used materials in FDM (Fused Deposition Modeling) 3D printing are PLA, ABS, and PETG. Each filament offers a unique balance of printability, strength, flexibility, and thermal resistance—and each comes with trade-offs. Use the wrong one, and you might face common issues like layer delamination, warping, brittleness, or poor surface finish.

In this comprehensive guide, we’ll walk you through:

● The core characteristics of PLA, ABS, and PETG

● How they perform across key properties like strength, temperature resistance, and print quality

● The best applications for each material

● Tips for choosing the right filament for your goals

● When to consider industrial-grade printing solutions

Whether you're just starting out or looking to scale your 3D printing workflow, this comparison will help you choose the right material with confidence and avoid costly trial-and-error.

Understanding PLA, ABS, and PETG

What is PLA?

PLA (Polylactic Acid) is a biodegradable thermoplastic derived from renewable resources like corn starch or sugarcane.

Source: Unionfab

It's known for its ease of use, low odor during printing, and environmental friendliness.

What is ABS?

ABS (Acrylonitrile Butadiene Styrene) is a widely used thermoplastic known for its strength, durability, and heat resistance.

It's commonly used in applications where high impact resistance is required.

Source: dienamics.com.au

What is PETG?

PETG (Polyethylene Terephthalate Glycol) is a durable thermoplastic that combines the strength of ABS with the printability of PLA.

Source: Unionfab

It offers excellent layer adhesion and is less prone to warping than ABS.

Key Properties Comparison of PLA, ABS, and PETG

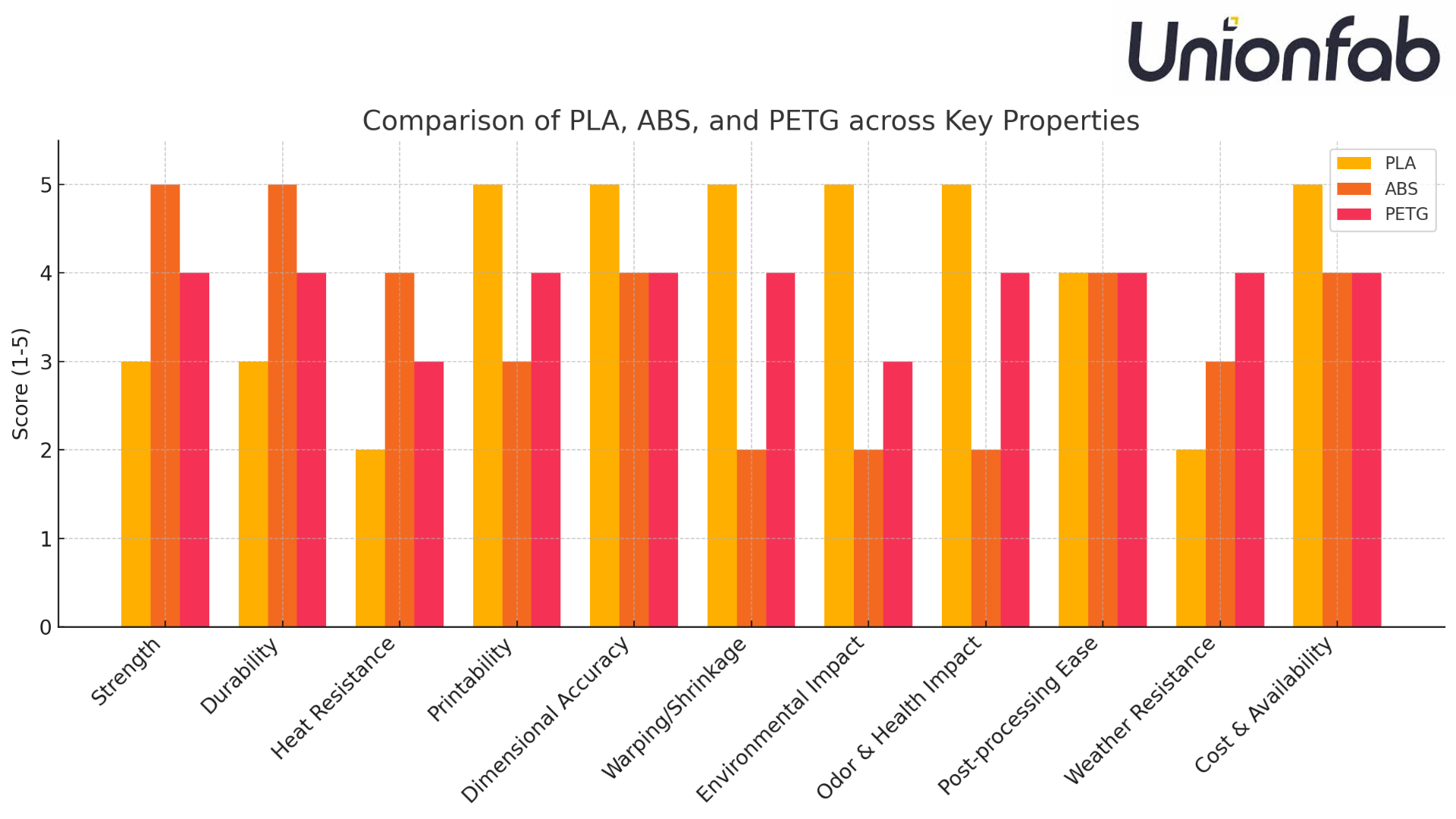

Property | PLA | ABS | PETG |

|---|---|---|---|

Composition | Renewable, biodegradable | Petroleum-based, not biodegradable | Petroleum-based, recyclable |

Strength | Moderate | High | Moderate to High |

Durability | Brittle | Tough | Tough & Slightly Flexible |

Heat Resistance | Low (~60°C) | Moderate (~100°C) | Moderate (~80°C) |

Printability | Very Easy | Moderate | Easy to Moderate |

Dimensional Accuracy | Excellent | Good | Very Good |

Warping & Shrinkage | Minimal | Prone to Warping | Low Warping |

Environmental Impact | Biodegradable & Eco-friendly | Petroleum-based & Non-Biodegradable | Recyclable but Not Biodegradable |

Odor & Health Impact | Very Low Odor | Strong Odor & Fumes | Minimal Odor |

Post-Processing Ease | Easy to Sand & Paint | Easy to Sand; Requires Vapor Smoothing | Good for Sanding & Gluing |

Weather Resistance | Poor | Moderate | Good UV and Weather Resistance |

Cost & Availability | Low & Widely Available | Moderate | Moderate to Slightly Higher |

Property Explanations

● Strength: Ability to withstand tension and pressure. ABS is the strongest; PLA and PETG are moderate to strong.

● Durability: Resistance to wear and impact. PLA is brittle; ABS and PETG are more robust and flexible.

● Heat Resistance: Maximum temperature tolerance. ABS has the best heat resistance, followed by PETG.

● Printability: Ease of printing success. PLA is the easiest; PETG is fairly easy; ABS can be tricky.

● Dimensional Accuracy: How well prints match design dimensions. PLA is highly accurate; PETG performs very well.

● Warping & Shrinkage: Tendency to deform during cooling. PLA is stable; ABS warps easily; PETG is stable.

● Environmental Impact: Biodegradability and sustainability. PLA is eco-friendly; ABS is not; PETG is recyclable but not biodegradable.

● Odor & Health Impact: Emissions and smell during printing. PLA has very low odor; ABS emits strong fumes; PETG has minimal odor.

● Post-Processing Ease: Suitability for sanding, painting, etc. PLA and PETG are easy to finish; ABS may require vapor smoothing.

● Weather Resistance: Outdoor durability. PETG excels in UV/weather resistance; ABS is moderate; PLA performs poorly.

● Cost & Availability: Price and market accessibility. PLA is the cheapest and most available; ABS and PETG are mid-range.

Get tailored recommendations from UNIONFAB experts and make the right choice for your next print.

Talk to Unionfab Experts

Post-Processing Tips

Sanding

All three materials - PLA, ABS, and PETG - can be sanded to achieve a smooth finish. PLA generally sands easily, while ABS and PETG may require more effort due to their higher strength.

Painting and Coloring

PLA, ABS, and PETG can all be painted and colored using various techniques. ABS may require additional surface preparation like sanding or priming for optimal results.

Support Removal

PLA, ABS, and PETG support different types of support structures, which can be removed manually or with support removal tools after printing.

Annealing

ABS and PETG can be annealed to improve strength and heat resistance. The annealing process involves heating the printed part to a specific temperature and slowly cooling it down.

Common Applications of PLA, ABS, and PETG (By Use Case)

1. Conceptual Prototyping

Materials: PLA, ABS, PETG

Why: Conceptual prototypes prioritize appearance and speed over strength. PLA is the most popular due to its excellent surface finish and ease of printing, while ABS and PETG are used when a bit more toughness is needed.

Use Cases:

● Design validation for appearance, form, and size

● Non-functional models for client presentations or internal reviews

Examples:

● PLA: Architectural models, product casing demos, ergonomic grip mockups

● PETG: Transparent component mockups, packaging prototypes

● ABS: Concept car interior parts, handheld electronics shells (non-functional)

2. Functional Prototyping

Materials: ABS, PETG (occasionally reinforced PLA)

Why: These prototypes need to endure physical stress, temperature variation, and limited operational testing. ABS offers heat and impact resistance; PETG adds flexibility and chemical durability.

Use Cases:

● Testing moving parts, snaps, or interlocking components

● Evaluating performance under real-world loads

Examples:

● ABS: Gears, mechanical joints, drone arms, robotics components

● PETG: Hinges, protective cases, chemical handling fixtures

3. End-Use Manufacturing

Materials: ABS, PETG

Why: ABS and PETG are tough enough for low-volume production or customized parts. PETG has better environmental resistance, while ABS is easier to finish.

Use Cases:

● Replacement parts, short-run product batches, and DIY manufacturing

Examples:

● ABS: Enclosures for electronics, vehicle clips, kitchen accessories

● PETG: Custom water bottles, brackets for outdoor equipment, tool holders

4. Educational Models

Materials: PLA (mostly), PETG (for higher durability)

Why: PLA is safe, easy to print, low-cost, and has minimal fumes, making it perfect for schools. PETG is suitable for more demanding classroom applications.

Use Cases:

● STEM teaching tools, demonstration models, 3D printing education

Examples:

● PLA: Geometry aids, biological cell models, historical artifacts

● PETG: Reusable mechanical kits, classroom robots, lab tools

5. Creative & Decorative Design

Materials: PLA, PETG, ABS (depending on finish and function)

Why: PLA offers a wide range of vibrant colors and matte finishes, perfect for artistic projects. PETG enables translucent/clear parts. ABS allows smooth surfaces with vapor treatment.

Use Cases:

● Sculptures, installations, home decor, design prototypes

Examples:

● PLA: Figurines, vase models, decorative lampshades

● PETG: Transparent ornaments, wearable fashion elements

● ABS: Post-processed sculptures, polished product mockups

6. Custom Tooling & Fixtures

Materials: ABS, PETG

Why: These prints need to handle physical stress, repeated use, and in some cases exposure to oils or cleaning agents. PETG is preferred when some flexibility is needed.

Use Cases: Factory floor tools, assembly aids, low-volume manufacturing tools

Examples:

● PETG: Jigs for aligning parts, protective packaging inserts, reusable shipping trays

● ABS: Positioning fixtures, calibration blocks, insert molds for short-run injection molding

How to Choose the Best Filament

Project Requirements

● Choose the filament that aligns with the specific needs of your project, considering factors such as required strength, durability, and heat resistance.

● Example: If your project involves creating load-bearing components or parts exposed to high temperatures, opt for ABS or PETG due to their superior mechanical properties compared to PLA.

Material Compatibility

● Ensure that the chosen filament is compatible with your 3D printer's specifications, including nozzle temperature range and heated bed requirements. Also, consider compatibility with any post-processing techniques you plan to use, such as annealing or vapor smoothing.

● Example: If your 3D printer has a heated bed and can reach higher extrusion temperatures, ABS or PETG would be compatible choices. Additionally, if you plan to post-process your prints with techniques like annealing, make sure the filament can withstand the heat without deforming.

Budget Constraints

● Take into account not only the upfront cost of the filament but also any additional materials or equipment required for printing and post-processing. Consider the overall value and performance of the filament relative to its cost.

● Example: While PLA may be more budget-friendly initially, ABS or PETG could offer better long-term value for projects that require enhanced durability.

Desktop vs. Industrial FDM 3D Printing

PLA, PETG, and ABS are the most commonly used materials for desktop FDM 3D printing. These machines are affordable and easy to use, making them a great choice for beginners and small projects.

However, desktop 3D printing also comes with some limitations, such as:

Drawbacks of Desktop FDM 3D Printing

● Small build volumes that restrict part size

● Limited accuracy and surface finish quality

● Narrow material compatibility, mostly restricted to standard plastics

● Slower print speeds that make batch production inefficient

By contrast, industrial FDM 3D printing offers significant advantages:

Advantages of Industrial FDM 3D Printing

● Large build volumes for big or multi-part assemblies

● Greater precision and repeatable, high-quality results

● Broad material compatibility, including engineering-grade and high-performance composites

● Faster print rates suitable for small-batch and mid-volume production

If your project requires larger parts, higher accuracy, or specialized materials, desktop 3D printers may not suffice. This is when it’s worth upgrading to industrial-grade FDM 3D printing.

At Unionfab, we provide advanced industrial FDM 3D printing services with a full range of materials and finishing options to meet all your functional and production-grade requirements.

Curious about the cost of industrial FDM 3D printing? Try Unionfab online free cost calculator below.

Calculate Your Cost

Conclusion

In conclusion, PLA, ABS, and PETG each offer unique properties and characteristics suited for different applications. By understanding the strengths and limitations of each filament, you can choose the right one to achieve optimal results for your 3D printing project.

3D Print with Diverse Materials at Unionfab

Unionfab, as a company specializing in the field of 3D Printing, is dedicated to providing high-quality 3D printing solutions for our customers.

Also, we can provide various types of 3D Printing materials you may need, such as PLA, PETG, and ABS of Fused Deposition Modeling (FDM) mentioned in this article.

Get an instant quote using our online tool, and start your 3D printing journey!

For further details, please feel free to reach out to us via our Contact Us page.