Annealing vs. Normalizing: Contrasts, Benefits, and Applications

This article explores the differences between annealing and normalizing, highlighting their benefits and best uses in industry.

Introduction

Annealing and normalizing are two critical techniques employed to modify the properties of metals. Understanding their disparities and applications is vital for optimizing manufacturing processes and achieving desired material characteristics.

Understanding Annealing

Definition and Purpose of Annealing

Annealing is a heat treatment process that involves heating a material to a specific temperature and then gradually cooling it to alter its microstructure.

The primary objectives of annealing include reducing hardness, improving ductility, eliminating internal stresses, and enhancing machinability.

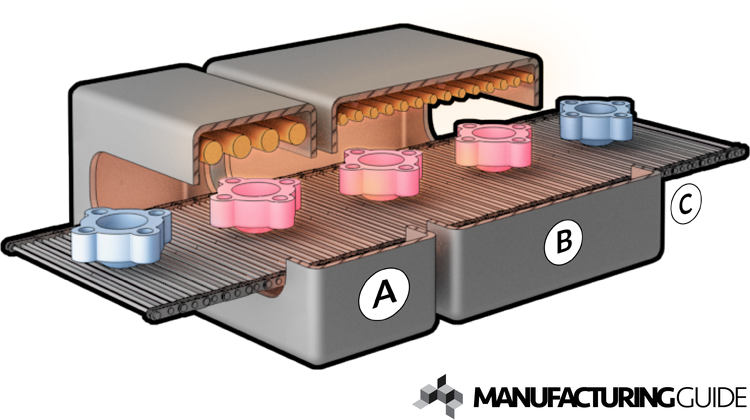

Mechanisms in the Annealing Process

During annealing, atoms within the material rearrange themselves, leading to the formation of new microstructures.

This process typically involves three stages: recovery, recrystallization, and grain growth.

Applications in Material Softening and Stress Relief

Annealing finds extensive use in industries requiring softened materials, such as in the manufacturing of steel, aluminum, and copper products.

It is also employed to relieve internal stresses accumulated during previous manufacturing processes.

Source: manufacturingguide.com

Understanding Normalizing

Definition and Objectives of Normalizing

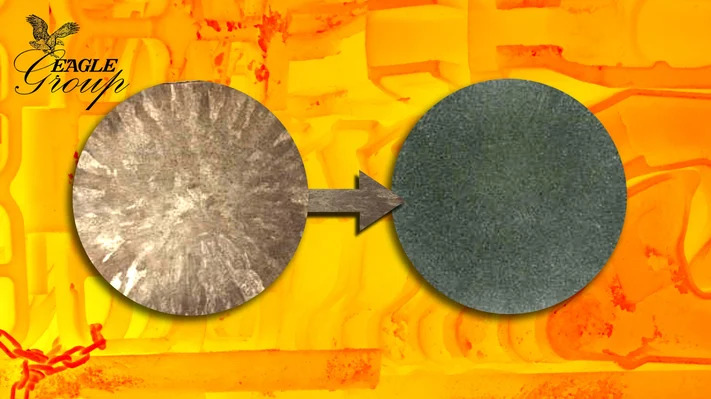

Normalizing is another heat treatment method aimed at refining the microstructure of materials. Unlike annealing, normalizing involves cooling the material in still air after reaching the desired temperature.

Its primary objectives include improving mechanical properties, such as hardness and strength, and achieving uniformity in the material structure.

Mechanisms in the Normalizing Process

Normalizing induces changes in the material's microstructure by promoting the formation of finer grains through controlled cooling.

This process helps in reducing grain size and enhancing mechanical properties.

Utilization for Improving Mechanical Properties and Uniformity

Normalizing is commonly utilized in applications where enhanced mechanical properties are essential, such as in the production of structural components and machinery parts.

It helps in achieving uniformity in material structure, resulting in improved performance and reliability.

Source: blog.eaglegroupmanufacturers.com

Annealing vs. Normalizing: The Contrasts

Aspect | Annealing | Normalizing |

|---|---|---|

Temperature | High | High |

Cooling Rate | Slow | Fast |

Microstructure | Coarse grain | Fine grain |

Material Properties | Ductile, Tough | Strong, Hard |

Pros | Machinable, Formable, Stress relief | Strong, Hard, Machinable |

Cons | Reduced strength, hardness | Reduced ductility, toughness |

Cost | High energy, Longer time | Lower energy, Faster |

Steel Comparison | Soft, Ductile | Hard, Strong |

Find perfection in finishing at Unionfab! Explore a wide range of metal finishing options like heat treatment, anodizing, polishing, and more.

Temperature and Cooling Rates

Annealing: Involves heating the material above its critical temperature and then slowly cooling it in a controlled environment like a furnace.The slow cooling rate allows for the formation of a coarse-grained microstructure.

Normalizing: The material is heated to a temperature slightly above its critical temperature and then allowed to cool in still air. This faster cooling rate results in a finer-grained microstructure compared to annealing.

Microstructural Changes and Effects on Material Properties

Annealing: Produces a coarse-grained microstructure, enhancing ductility and toughness while reducing hardness and strength. It also relieves internal stresses, making the material more machinable and formable.

Normalizing: Results in a finer-grained microstructure, which improves both strength and hardness. However, it may not provide the same level of ductility and toughness as annealing.

Pros and Cons

Pros

Annealing: Improved machinability and formability, increased ductility and toughness, stress relief.

Normalizing: Enhanced strength and hardness, improved machinability.

Cons

Annealing: Reduced strength and hardness.

Normalizing: Potential reduction in ductility and toughness compared to annealing.

Comparison of Cost

Annealing: Annealing typically requires longer processing times and more energy due to slower heating and cooling rates.

Normalizing: Normalizing is quicker and may have lower energy costs, but the faster cooling rate can increase the risk of distortion, requiring additional machining or processing steps.

Annealed vs. Normalized Steel

Annealed Steel: Softer and more ductile, making it easier to machine and form. It has improved toughness due to its coarse-grained microstructure.

Normalized Steel: Harder and stronger than annealed steel, suitable for applications requiring higher strength. However, it may be less ductile and tough due to its finer-grained microstructure.

Annealing vs. Normalizing: Applications

Automotive Industry

Source: Unionfab

Annealing: Used to soften steel components like engine parts, improving machinability and reducing internal stresses.

Normalizing: Applied to enhance the strength and hardness of structural components such as chassis and axles, ensuring durability under harsh conditions.

Aerospace Sector

Annealing: Utilized for stress relief in aircraft engine turbine blades, enhancing fatigue resistance and extending service life.

Normalizing: Employed in the production of high-strength aluminum alloys for aircraft structures, improving mechanical properties and structural integrity.

Construction Field

Annealing: Commonly used in the fabrication of structural steel beams and columns, reducing hardness and facilitating welding and forming processes.

Normalizing: Applied to reinforce steel reinforcement bars (rebars) used in concrete structures, enhancing tensile strength and resistance to deformation.

Manufacturing Sector

Source: Unionfab

Annealing: Employed in the production of precision tools and dies, improving machinability and reducing wear during machining operations.

Normalizing: Used in the manufacturing of gears and shafts to achieve desired hardness and strength, ensuring reliable performance in heavy-duty applications.

Annealing vs. Normalizing: Selecting the Right Treatment

Several factors influence the selection of annealing or normalizing treatment:

Material Type and Composition

Different materials, like carbon steel versus stainless steel, react differently to annealing and normalizing due to variations in their compositions and alloying elements.

For instance, some alloys may require normalizing for optimal properties, while others may benefit more from annealing.

Desired Mechanical Properties

Depending on the application's requirements, you may prioritize specific mechanical properties. Annealing tends to improve ductility and machinability, while normalizing enhances hardness and strength.

Consider the balance needed between these properties for your application.

Structural Integrity Requirements

If your application necessitates high structural integrity and load-bearing capacity, normalizing might be preferred due to its ability to refine the material's microstructure and enhance mechanical properties uniformly.

Application Environment and Conditions

Source: Unionfab

Factors like operating temperature, pressure, and mechanical stresses in the application environment influence the choice between annealing and normalizing.

For instance, components subjected to high temperatures or cyclic loading may benefit from normalizing to ensure superior mechanical performance.

Production Timeline and Cost Considerations

Annealing offers cost-effectiveness with slower cooling rates, while normalizing may be necessary for specific properties despite higher costs and faster cooling. Evaluate production timelines, costs, and material needs to decide wisely.

In conclusion, when choosing between annealing and normalizing, consider factors like material composition, desired properties, structural integrity needs, application environment, and cost. Annealing enhances ductility and machinability, while normalizing improves hardness and strength.

Striking the right balance among these factors ensures optimal treatment selection for your application.

Conclusion

Annealing and normalizing are indispensable heat treatment techniques that play vital roles in shaping the properties of metals to meet specific manufacturing requirements.

By understanding their differences, advantages, and applications, manufacturers can optimize production processes and achieve high-quality product outcomes.

Unionfab: Your One-Stop Manufacturing Partner

At Unionfab, we specialize in 3D printing, CNC machining, and other manufacturing services, offering a complete production journey from prototyping to finishing. Our value-added services include expert heat treatments like annealing and normalizing to ensure your parts meet the highest standards of durability and performance.

With 20+ years of experience, Unionfab is your trusted partner for precision manufacturing.

How to Add Heat Treatment to Your Quote

Adding heat treatment, such as annealing or normalizing, is simple with our instant quoting system:

Click “Get Instant Quote” on our toolbar or here.

Upload your 3D model or select an existing project.

Choose your desired item, click “Edit Item,” and select Heat Treatment from the finishing dropdown menu.

Click “Apply” to confirm your choice.

Need a more detailed guide? Refer to our Step-by-Step Guide for a comprehensive walkthrough.

Contact us to learn how we can elevate your projects!

.