3D Printing Revolutionizing Orthotics Manufacturing

Orthotics, the field of medical devices focused on enhancing neuromuscular and skeletal systems, has been significantly transformed by 3D printing technology.

Introduction

Orthotics, the field of medical devices focused on enhancing neuromuscular and skeletal systems, has been significantly transformed by 3D printing technology.

This article explores the various processes involved in 3D printed orthotics, their applications, advantages, and the evolving trends in digital design technology.

Functions and Types of Orthotics

Functions of Orthotics

Orthotics serve several functions:

Stabilization and Support

Restrict abnormal movement to maintain joint stability and weight-bearing ability.

Fixation and Correction

Correct deformities or prevent their progression by immobilizing affected areas.

Protection and Load Exemption

Immobilize limbs or joints, maintain alignment, and relieve weight-bearing joints.

Reparation and Assisted Movement

Use devices like rubber bands or springs to compensate for muscle loss and assist limb movement.

Types of Orthotics

Upper Extremity Orthoses

Shoulder, Elbow, Wrist, and Hand Orthosis

Elbow Wrist Hand Orthosis

Wrist-Hand Orthosis

Hand Orthosis

Lower Extremity Orthotics

Hip, Knee, Ankle, and Foot Orthosis

Knee Orthosis

Knee-Ankle-Foot Orthosis

Ankle-Foot Orthosis

Foot Orthosis

Spinal Orthotics

Cervical Orthosis

Thoracolumbosacral Orthosis

Lumbosacral Orthosis

3D Printed Orthotics: Why and How

Advantages of 3D Printed Orthotics

Rapid Customization: The inherent flexibility of 3D printing technology allows for swift adaptation to individual anatomical requirements. Each orthotic device can be precisely tailored to suit the unique needs of the patient.

Functional Integration: 3D printed orthotics seamlessly integrate various functional elements into a single design. This enables the incorporation of specialized features that enhance support, movement, and therapeutic outcomes.

Lightweight Design: Leveraging advanced materials and precise layering, 3D printed orthotics maintain their structural integrity while remaining remarkably lightweight. This not only enhances wearer comfort but also minimizes the impact on natural movements.

Improved Comfort: The ability to intricately design orthotic structures ensures a more ergonomic fit, reducing pressure points and discomfort commonly associated with traditional devices.

Aesthetic Appeal: 3D printing allows for creative design possibilities, enabling orthotics to be visually appealing and harmoniously blend with clothing and personal style.

Types of 3D Printing Processes for Orthotics

Material Extrusion Processes

Fused Filament Fabrication (FFF)

Materials: PA, PP, TPU, fiber-reinforced composite materials

Powder Bed Processes

High-Speed Sintering (HSS)

Multi-Jet Fusion (MJF)

Materials: PA12, TPU powder

VAT Photopolymerization Processes

Digital Light Synthesis (DLS)

Materials: Elastic photosensitive resin

Process for 3D Printed Orthotics

Examining the patient's condition

Prescribing customized orthoses

Acquiring patient imaging data through 3D scanning

Designing personalized orthotic models

3D printing the orthosis

Post-processing

Fitting the orthosis to the patient

Monitoring and feedback for adjustments

Applications of 3D Printed Orthotics

Foot and Ankle Orthosis (AFO)

Foot and ankle orthosis, commonly referred to as AFO, is a specialized orthotic device designed for patients with ankle soft tissue injuries and foot instability. Its application extends to personal protective care during sports activities.

Clinical Applications

AFOs are beneficial in treating various conditions including:

Cerebral palsy

Stroke

Fractures

Spinal cord injuries

Peripheral nerve injuries

Types of Ankle Foot Orthosis

There are several types of AFOs, including:

Passive AFO (hinged and non-hinged)

Semi-active AFO

Active AFO

Manufacturing Requirements for AFOs

Strength for providing adequate support

Flexibility to ensure comfort during walking

Breathability to prevent excessive sweating

Lightweight design to minimize energy expenditure while walking

Aesthetic appeal for seamless integration into clothing

Ease of customization and molding

Evolution of AFO Manufacturing

The production of Ankle Foot Orthoses (AFOs) has progressed significantly. It started with molding thermoformed plastic sheets around plaster casts. Then, pre-impregnated carbon fiber sheet laminates were shaped around plaster casts for increased durability.

Currently, direct 3D printing is the cutting-edge method, enabling efficient and personalized AFO fabrication. This evolution highlights the continuous pursuit of enhancing orthotics through technological advancements.

Spinal Orthoses

Spinal orthoses are globally acknowledged as effective treatments for scoliosis, a condition characterized by abnormal spinal curvature.

Advantages and Challenges of 3D Printed Spinal Orthoses

3D printed spinal orthoses offer distinct advantages:

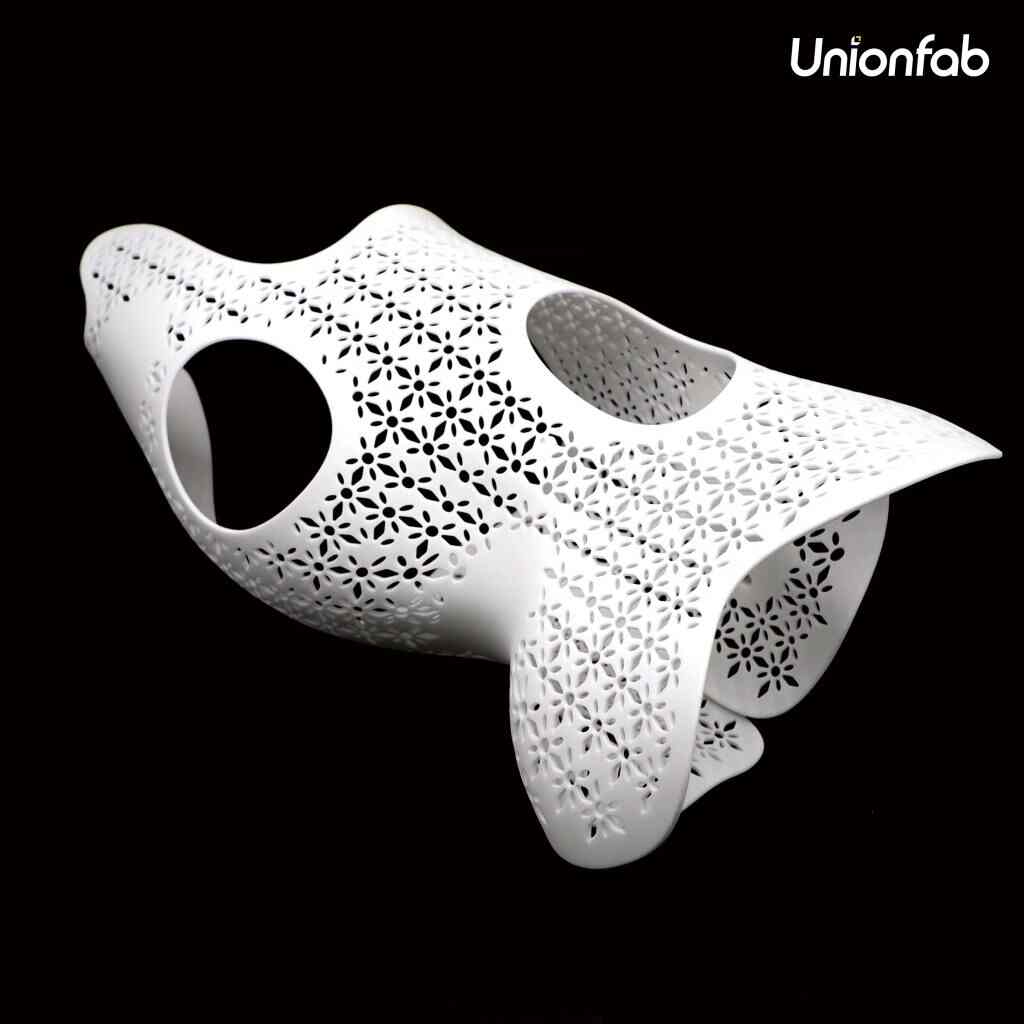

Customized and comfortable scoliosis orthoses tailored to individual needs and biomechanical analysis.

Utilization of diverse production materials to meet varying patient material requirements.

Porous design enhancing breathability and reducing skin and soft tissue complications.

Simpler, faster, and cleaner production process aligned with human body characteristics and treatment needs.

However, 3D printed spinal orthoses face certain challenges:

Longer processing cycles compared to traditional methods

Higher costs due to the expense of materials

Spinal Orthoses Manufacturing Methods

Various manufacturing methods for spinal orthoses include:

Gypsum Process (Manual Process):

Plaster bandage

Model creation

Plaster paste application

MoldingCAD/CAM (Digitizing):

3D scanning for data acquisition

CAD design

Model machining

MoldingCAD/3D Printing (Digitizing):

3D scanning for data collection

CAD design

3D printing

Hand Orthoses

Applications of Hand Orthoses

Hand orthoses find therapeutic applications in treating:

Fractures

Sprains

Ligament injuries

Misalignment

Advantages of Hand Orthoses

Lightweight design

Waterproof properties

Compatibility with X-rays

Wearability under clothing

Facilitation of limited movement

Trends in Digital Design Technology for Orthotics

Digital design and manufacturing of orthotics involve computer-aided design/manufacturing, 3D scanning, medical modeling, and finite element analysis.

Early adoption saw manual trimming but has shifted to software-based trimming due to advancing software and AI-driven design tools. Software aids in comparing body scans and X-rays, reducing design errors.

Utilizing 3D Scanning for Patient Data

3D scanning for patient data acquisition eliminates secondary injuries and improves accuracy compared to manual methods.

This enhances orthotics customization, fit, comfort, and therapeutic effectiveness.

Conclusion

3D printing has revolutionized orthotics manufacturing, offering customized solutions with functional benefits. As technology advances, orthotics design and production will continue to become more efficient, patient-centric, and effective.