The application of 3D printing technology in the medical field began in the late 1980s and was initially primarily used to produce medical 3D models rapidly. At that time, 3D Printing Technology was primarily used to help doctors communicate with patients, accurately diagnose illnesses, and plan the surgery. The application of 3D printing technology in the medical industry has long been explored worldwide, but now it is even more profound.

With the development of 3D printing technology and the growing demand for accurate and personalised treatments in recent years, the application of 3D printing technology in the healthcare industry has grown significantly in both breadth and depth. In terms of the scope of applications, it has gradually evolved from the first rapid production of medical models to the direct output of 3D printing of hearing aid shells, implants, complex surgical devices, and pharmaceuticals. Furthermore, the manufacture of inanimate medical devices by 3D printing is evolving profoundly towards the printing of biologically active artificial tissues and organs.

Classification of 3D Printing Applications

Medical Model

The 3D printing technology of the medical model intuitively reproduces the specific situation of the lesion, effectively reduces the risk of surgery and solves the surgical confusion of patients and their families. Currently, most CT and MRI results look like black-and-white photographs, but complex lesions can still be unfair.

Mr Wang, head of the Unionfab medical project, said that preoperatively, based on the patient's CT or MRI data, a 3D data model suitable for 3D printing was synthesised by software and printed with a 3D printer. As a result, he achieved an accurate medical model. It is helpful for doctors' planning because it allows you to visually check the three-dimensional structure of the surgical area before surgery. Especially for complex surgery, it helps reduce the risk and increase the success rate of surgery.

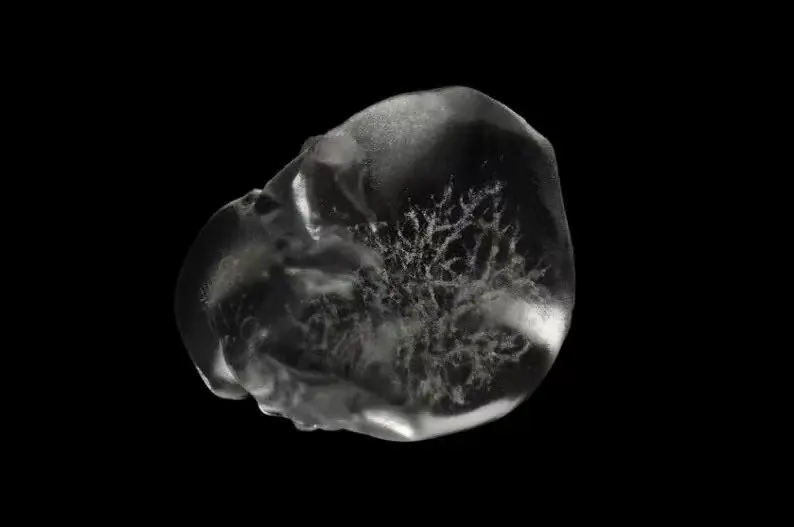

In 2015, Shanghai General Hospital reportedly used 3D printing technology to perform a living-donor liver transplant for a patient suffering from congenital autoimmune cirrhosis and portal hypertension. 3D printing technology was used to create the surgical plan before surgery. 3D printing presents the patient's hepato-biliary-pancreatic organs and corresponding affected areas to the physician in a 1:1 "physical" format. Physical Geometry accurately assesses the three-dimensional spatial relationship between the lesion mirror and adjacent organs and tissues, allowing real-time comparisons during surgery. Align the 3D printed model and place it in the optimal anatomical position for rapid identification. Locate critical parts and provide intuitive real-time navigation for necessary surgical steps. Accurately identifying lesions and vessels and controlling critical vascular connections in real-time can improve surgical accuracy and reduce surgical risks effectively.

Surgical Stent

Surgical stents are a vital tool for doctors. As a powerful tool for precision surgery, surgical stents are digitally designed, and 3D printed based on 3D reconstruction and surgical simulation to help physicians perform accurate surgery and reduce surgery time.

3D surgical stents are more cost-effective if:

-Complex design that conventional methods cannot achieve

-Meet the needs of a particular disease or the individual needs of a patient

-Functionally integrated design

3D printing technology is especially suitable for producing specially shaped or personalised guardrails.

Rehabilitation Device

With the rapid development of digital and medical technology, 3D printing technology has been widely used in the medical field. With the help of 3D printing technology, doctors can turn virtual images into physical models, creating a new approach to surgical treatment and follow-up rehabilitation that is different from traditional methods, bringing new concepts and working modes to the medical field. As far as surgical restoration is concerned, 3D printing technology can completely simulate the characteristics of the patient's rehabilitation brace made by 3D printing can increase the individual accuracy of the brace that enables the patient to obtain a "personally customised" rehabilitation experience.

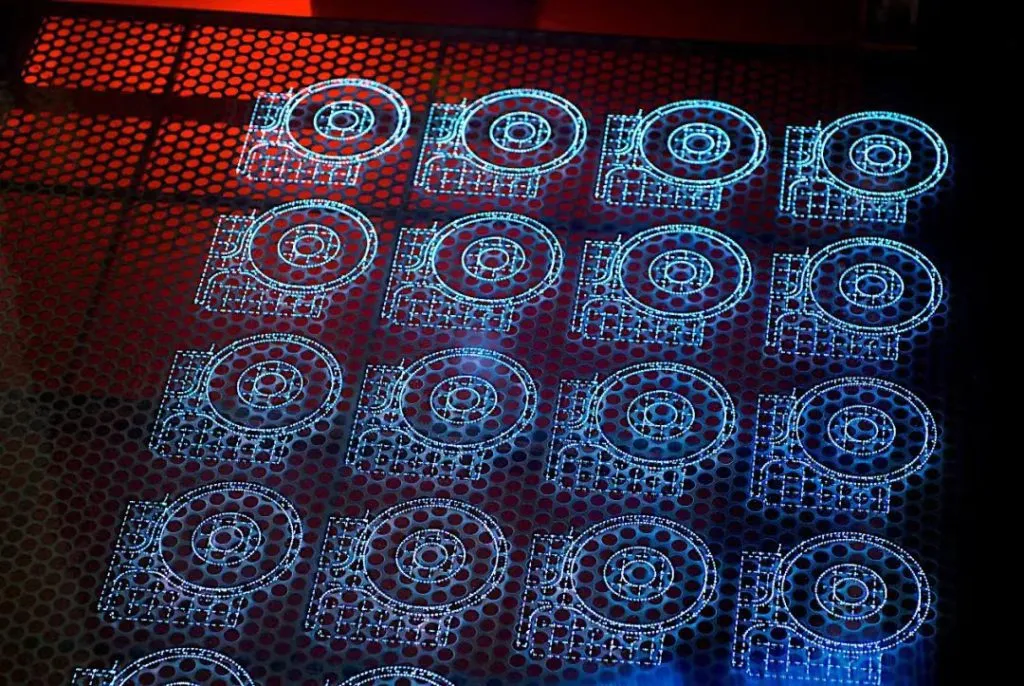

3D rehabilitation device includes orthoses and bionic hands, personal mobility aids, communication and information aids, personal medical aids and other rehabilitation aids. The real value brought is the realisation of precise customisation, replacing hand-made methods with straightforward and efficient digital manufacturing technology, and shortening the production cycle. For example, Unionfab's 3D printing technology can print 70 earmuff shells or hearing protection models in about 60 minutes. As a promising individual adjunctive treatment, 3D rehabilitation devices are essential in modern medicine.

Dentistry

Due to the rapid development of digital technology and its application to oral medicine, various 3D imaging and optical scanning technologies have enriched the method of collecting oral clinical data, and 3D printing technology has become one of the hot spots in oral medicine. I am. It will be an application. Many advanced dental clinics and laboratories employ digital oral technology to improve efficiency and save costs. In addition, stereolithography appearance techniques are widely used in diagnosing and treating prostheses. Also, they are commonly used to manufacture clinical diagnostic models, mechanical working models, padding press models, and other oral models such as guideboards, temporary crowns, and orthodontics. Integrate 3D digital printing technology into your digital dental process for accurate and efficient production.

Medical Apparatus

Like other products, medical devices need to be prototyped during the development phase of a new product for design verification. 3D printing is a cheap and fast way to prototype your product. Stereolithography appearance technology is widely used in medical devices due to its high precision and excellent surface quality. It provides an effective solution for products that can complete rapid prototyping and mass production.